Total Titratable Acidity (TTA)

What is Total Titratable Acidity (TTA)?

Total titratable acidity (TTA) is a measure of the amount of acid or acids present in a food sample. It is not to be confused with pH, a measure of the concentration of hydrogen ions.

The acidity of food products is a consequence of their formulation, including the amount and type of ingredients, additives, and preservatives used. Also, the processing conditions. Several baking operations rely on the TTA parameter to control their process, such as:

- Preferments

- Leavening (yeast or chemical)

- Flavor development as related to acids present

- Product formulation (e.g. correct use of buffering ingredients)

How does it work?

TTA determination is centered on the amount of base (not its strength) required to neutralize the acid(s) in a sample. It is reported as milliliters (mL) of a solution of concentration 0.1 normal (N) of sodium hydroxide (NaOH), required to neutralize a material to a pH of 6.6.1

The difference between TTA and pH

TTA and pH are two interrelated concepts that deal with acidity. However, they give different insights into the composition of the sample.2 pH is used to measure how strong or weak acids are, and how acidic or alkaline foods are. This is done by measuring the concentration of hydrogen ions (H+) that they release in an aqueous solution. On the other hand, TTA indicates the amount of acid present, which does not necessarily correspond to the concentration of the hydrogen ions.

TTA as fermentation control mechanism

TTA is a reliable way to control the extent of fermentation and acidity developed in preferments. Unlike pH, TTA is not impacted by the presence of buffers in the sample being analyzed. This is a particularly useful tool for controlling the fermentation of bakery systems such as plastic sponges, sourdough, poolish and flour brews containing natural buffering ingredients (e.g. flour, eggs, vital wheat gluten, non-fat dry milk).

The higher the TTA, the stronger the fermentation flavors. Also, highly acidic preferment or dough (of high TTA) would exhibit a tart or sour taste.

Application

The following is an overview of TTA and its relationship with pH through a bread making processes using a sponge and dough system:

| Process step | TTA (mL)1 | pH1 | Comments |

| Bread sponge | 4.5–4.6 | 4.8–4.9 | At the end of fermentation, the sponge becomes more acidic. More base is needed to neutralize the organic acids produced, and pH is lower than that of dough. |

| After dough makeup and mixing | 3.9– 4.0 | 5.2–5.6 | With the addition of fresh flour, side water, milk solids, vital wheat gluten, etc., the dough loses some of the sponge’s acidity. TTA decreases and pH increases, approaching neutral values. |

| After proofing | 5.0–5.5 | 4.9–5.0 | Acidity builds up slightly after proofing, and more base is needed to neutralize the acid produced by the end. |

| Baked good (bread) | 3.8–3.9 | 5.1–5.2 | Baking evaporates some water, alcohol, and volatiles as well as water-soluble compounds. Therefore, the bread loses some of the acidity gained during final proofing. |

TTA of liquid preferments (flour and water brews)

TTA is very useful for measuring total acids produced by yeast and lactic acid bacteria fermentation. In this application, TTA is also used to assess fermentation rate and determine when preferments are fermented and matured to optimum levels.

| Flour brew | TTA (mL) | pH |

| Initial settings | 3.0–4.0 | 5.0–5.5 |

| Final (fermented) | 6.0–10.0 | 4.4–4.8 |

| Water brew | ||

| Initial settings | 3.0–4.0 | 5.0–5.5 |

| Final (fermented) | 10.0–12.0 | 3.8–4.4 |

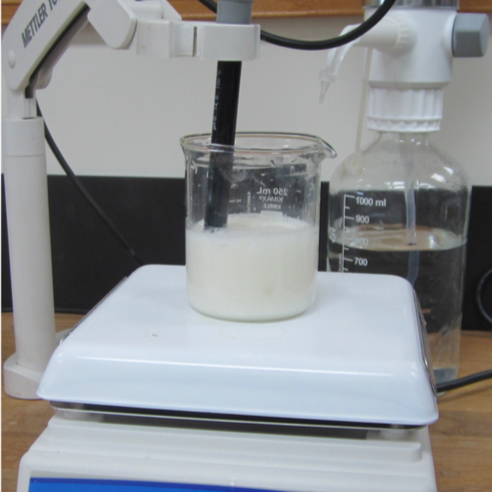

Measuring TTA

Equipment

- pH meter (end point indicator)

- Magnetic stirrer and stirring bar

- 150 mL Erlenmeyer flask or plastic container

- Graduated cylinder

- Analytical scale

- Burette, ring stand, burette clamp

- 0.1 N Sodium hydroxide (NaOH)

- Distilled or reverse osmosis (RO) water

- pH standard buffers

Procedure

- Sample preparation (particle size reduction, homogenization)

- Weigh sample into flask or plastic container

- 15 g batter, sponge, dough, cake, etc.

- 20 g brew, poolish, sponge

- Add 100 mL RO or distilled water for non-finished product, or 150 mL water for baked goods

- Shake and blend mixture until a relatively homogeneous suspension is attained

- Add stirring bar

- Turn on stirring device to prevent particles from sinking

- Carefully insert pH electrode (equipment must have been properly calibrated)

- Record initial pH

- Titrate with 0.1 N NaOH

- Record volume of based used (mL) to reach end point (pH 6.6)

- Make sure pH remains stable (unchanged) at the final pH

References

- Cauvain, S.P. “Speciality Fermented Goods.” Technology of Breadmaking, 3rd edition, Springer International Publishing Switzerland, 2015, pp. 253–256.

- Tyl, C. and Sadler G.D. pH and Titratable Acidity. In: Nielsen S. (eds) Food Analysis. Food Science Text Series. Springer, Cham, 2017, pp, 389-406.