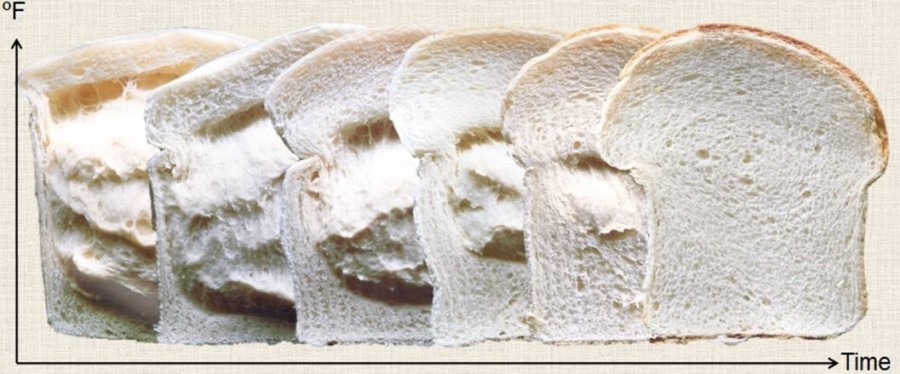

There’s a relationship between the time spent in the oven and the moisture of your product. This relationship is best illustrated with what’s known in the industry as thermal profiling, or the S Curve. Here’s the break down:

- The product goes into the oven.

- As the oven goes through it’s mechanisms of convection, conduction and radiation, the internal temperature of the product increases.

- Within the critical change zone, the temperature changes more dramatically, starting with the yeast kill and ending with the bake out towards the end.

The key with using the S Curve is manipulating the bake out (or arrival). Too much bake out, and the product may dry out. And too little of a bake out will open the door for microbial spoilage. So, there needs to be trial and error to determine the length of this zone, and this varies from one product to another.

Using the S Curve to improve products

A common problem experienced by bakers is over baking. This shortens shelf life and produces a crumbly product. You can prevent over baking by using a thermal profile, and achieving a bake out of no more than 15%. This can be done by increasing oven temperatures and shortening baking times.

If molding is a big issue, use the thermal profile to achieve more than 15% bake out. This can be achieved by reducing the end zone temperatures and increasing the baking time.