Thermal Profiling for Partially Baked and Frozen Dough Products

Why Temperature Measurement During the Partial Baking and Freezing Processes is Crucial for Outstanding Results

The convenience and easy preparation associated with frozen dough products are driving the category’s solid growth in the baking industry, with analysts projecting 5%+ CAGR through 2034. Likewise, partially baked (or pre-baked) varieties are also seeing a rise, with estimates of similar expansion at 4% through 2033 – and that’s just for North America! Among the many reasons that frozen and par-baked dough products are on the upswing are their affordability, versatility, simplicity for the consumer, long storage life, and bakery customization options.

Ensuring the best results for par-baked and frozen dough bread products requires the precision of specialized sensors and a portable thermal profiler (data logger) to measure internal dough temperature during the freezing process (in the case of frozen dough) and the partially baked bread’s baking and cooling processes. By precisely measuring dough’s exposure time at specific temperatures during different cycles, bakers can ensure the desired texture, structure, and quality once the products are baked to their final form.

Par-Baked Product Precision

While par-baked products typically experience most of the whole baking process – approximately 80% to 90% – before being rapidly cooled or frozen to suspend further transformation, the baking parameters vary from the standard baking routine for fully baked bread products. As with all baking processes, the exact time/temperature exposure specifications for par-baked varieties depend on the bread type and its ingredients, along with expected storage, and final baking conditions.

While par-baked products typically experience most of the whole baking process – approximately 80% to 90% – before being rapidly cooled or frozen to suspend further transformation, the baking parameters vary from the standard baking routine for fully baked bread products. As with all baking processes, the exact time/temperature exposure specifications for par-baked varieties depend on the bread type and its ingredients, along with expected storage, and final baking conditions.

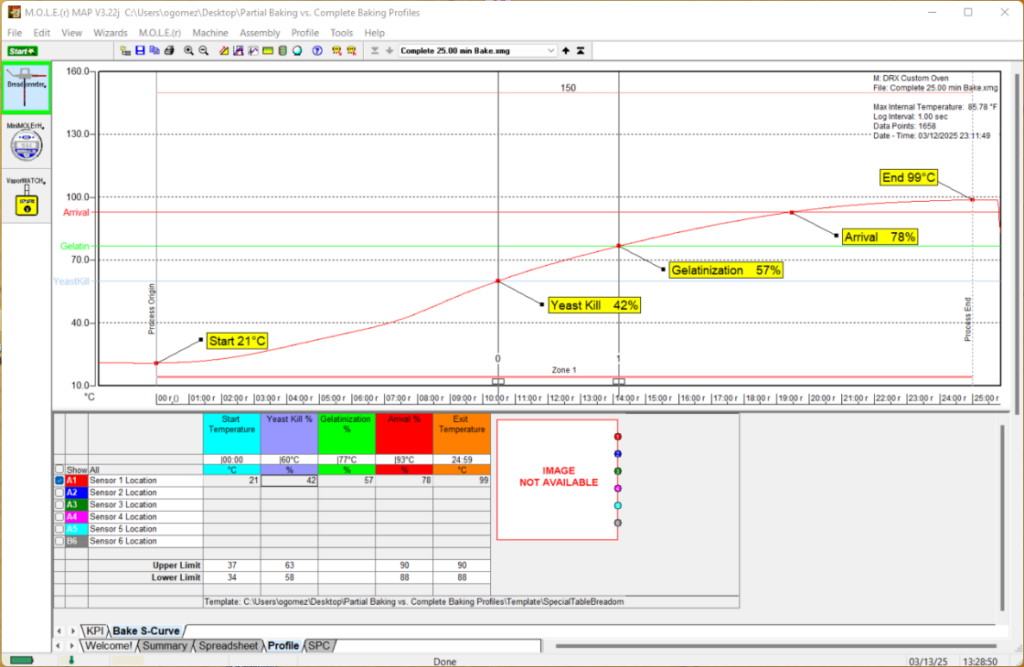

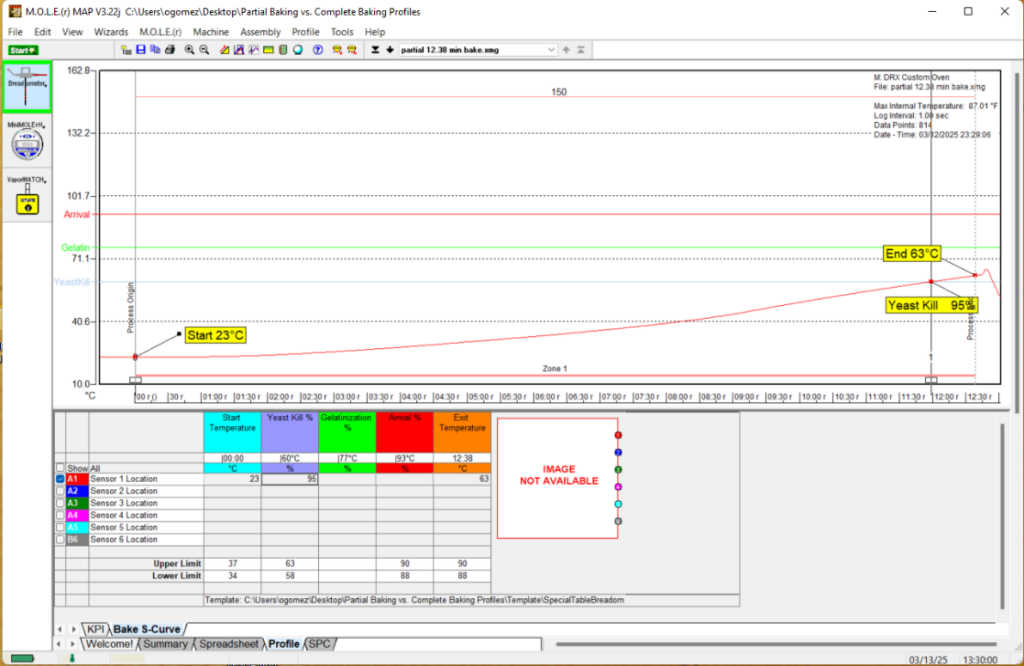

Usually, par-baked bread products, such as dinner rolls, pizza crusts, and bake-on-site loaves, are baked at lower temperatures than traditional bread baking. This avoids potential over-baking and ensures mild crust formation and partial gelatinization while not fully achieving the final crumb structure. Compared to standard baking, par-baked varieties are baked for 50-75% of the full bread baking time, and internal dough temperatures are also tightly controlled to ensure stability while not being fully baked. Finally, humidity parameters are optimized for control of crust formation and ample moisture retention, while rapid cooling to the set post-bake temperature stops the baking process. The below S-Curve graphs, captured with M.O.L.E.® thermal profiling equipment, show the difference between fully baking and par-baking bread and illustrate why accurate time/temperature exposure data is so important.

S-Curve for fully baked bread, 25 minute baking cycle: Set point 150° C, completed three baking phases of completing three baking phases of Yeast Kill, Gelatinization and Arrival.

S-Curve of partially baked bread, 12 min., 38 sec. bake cycle. After Yeast Kill, only partial Gelatinization occurs and, clearly, there is no Arrival, hence not shown on the graph. Profiling can indicate the precise time the baking cycle should be halted. Bread can be immediately frozen after this interrupted bake and completed at the consumer site.

Adhering to these steps with tight control of exposure time and internal dough temperature is vital to maximizing shelf-/storage-life and securing high-quality bread texture, taste, crust, and color. The only way to meet the specific milestones for par-baked bread products is through precision measurement enabled by thermal profiling tools.

Frozen Dough Freeze Control

For doughs that will remain frozen until fully baked at their final destination, carefully controlling dough temperature and ensuring precise freezing is vital. Properly freezing doughs and batters is as crucial to finished product quality as the baking step, and thermal profiling facilitates a well-managed freezing operation. Water (flour hydration), sugars, salt, and other enriching ingredients, like fats and eggs, all affect the freezing time and energy consumption. In baked goods, the higher the concentration of sugars, salt, fats, polysaccharides, and proteins, the lower the freezing point. In this case, additional freezing time is needed, and more energy must be expended to achieve a final temperature. Profiling ensures that all variables are aligned, balancing ingredient variables with freezing cycle times and temperatures to deliver the highest quality results once the dough is thawed and baked.

For doughs that will remain frozen until fully baked at their final destination, carefully controlling dough temperature and ensuring precise freezing is vital. Properly freezing doughs and batters is as crucial to finished product quality as the baking step, and thermal profiling facilitates a well-managed freezing operation. Water (flour hydration), sugars, salt, and other enriching ingredients, like fats and eggs, all affect the freezing time and energy consumption. In baked goods, the higher the concentration of sugars, salt, fats, polysaccharides, and proteins, the lower the freezing point. In this case, additional freezing time is needed, and more energy must be expended to achieve a final temperature. Profiling ensures that all variables are aligned, balancing ingredient variables with freezing cycle times and temperatures to deliver the highest quality results once the dough is thawed and baked.

Frozen dough suppliers understand that product quality directly relates to ingredient optimization and the ideal freezing conditions for specific dough formulations. Controlling key aspects of freezing, like the rate of temperature drop and the final internal temperature, directly impacts dough structure and ingredient viability. Thermal profiling can enhance the freezing process and ensure its success by providing data that verifies freezing parameters for complete control.

These parameters include:

- Freezing cycle time

- Freezer temperature (set point)

- Rate of temperature decrease (slope)

- Internal temperature of product (key if formulation changes are implemented)

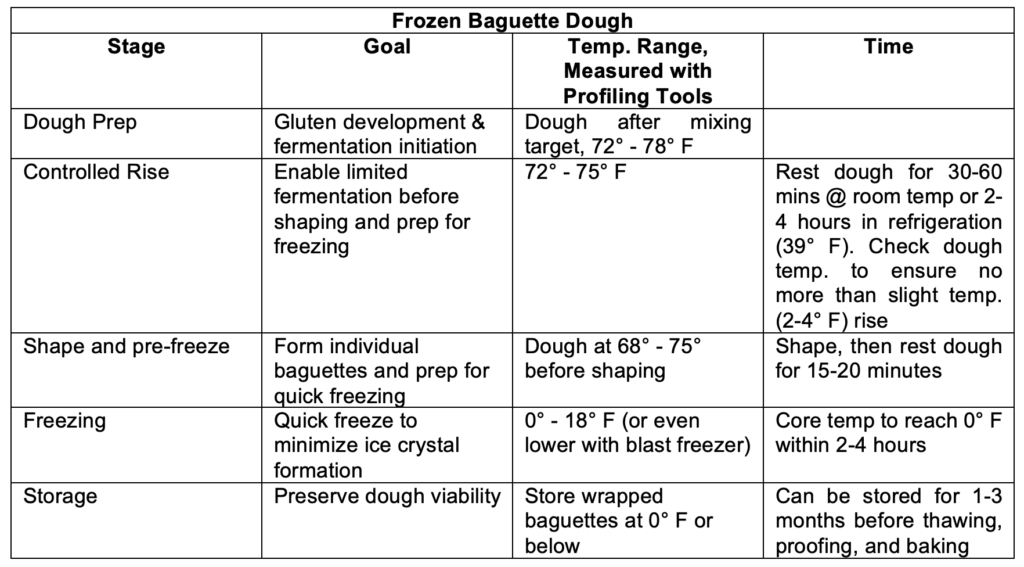

In the freezing process, the product loses sensible heat to its cold surroundings and its temperature decreases, starting from regular dough mixing temperatures (75–80° F) and finishing with a temperature of –0.4 to –9.4°F. The product then goes through the critical temperature zone, the temperature range during which its core reaches and surpasses the freezing point (giving up latent heat) to reach its final ideal frozen temperature. The example below illustrates the typical stages of frozen baguette dough:

Whether Par or Frozen, Data Makes All the Difference

Thermal profiling tools like those offered by ECD are widely used for baking profiling and are also ideal for par-baked and frozen dough process control. It’s also important to note that consistency across every loaf or roll in the process is vital. Many loaves are processed simultaneously in oven chambers or freezers, and the only way to determine process uniformity for all in-process products is by measuring and comparing internal heat transfer in each region with sensors and data capture technology. In precision processes, such as partial baking, over or under baking products in the same batch can result in inconsistent yields. This is why thermal profiling products in freezers, proofers, and ovens is so vital, as it allows corrective actions to resolve any deviations so that profitability can be protected.

A thermal profiler like ECD’s touchscreen M.O.L.E.® EV6, in combination with a BreadOMETER® sensor, can capture data about the dough’s response to the cooling, par-baking, proofing and/or freezing environments and ensure a consistent core temperature and uniformity across all dough and bread pieces.

The objective is to KNOW YOUR DOUGH and thermal profiling data is key to this knowledge.

Deliver partially baked and frozen dough products with confidence. Learn more about thermal profiling solutions here.

Ready to speak with a baking thermal profiling expert? Connect with a thermal profiling pro.

|

About the Author Oscar Gomez is the Product Manager for ECD’s Baking Division. He has extensive thermal profiling experience, having worked with a Mexican industry representative/distributor company supporting large commercial bakeries in their process optimization objectives. Oscar joined ECD in 2022 and, in addition to his Baking Division role, supports Latin American electronics customers. |