Oven Air Velocity

Also known as oven convective airflow

What is Oven Air Velocity?

Oven air velocity is defined as the flow rate of air in an oven chamber and is expressed in m/sec or ft/min. Measuring air velocity along with other oven parameters such as heat flux, humidity and temperature can have a significant impact on controlling:

- Amount of convective heat delivered to the product

- Moisture removal

- Crust formation

- Overall bake of the final product

How it works

In a convection oven, for example, air velocity is a measure of how much air moves along and across the baking chamber. In terms of equipment, fans and blowers create hot air recirculation in the baking chamber. The faster the air moves, the higher the convective heat flux the product receives for a proper bake.

Increasing air velocity leads to an increase in the apparent heat transfer coefficient (h); hence making convective heat flux higher.1,2 This is certainly beneficial in processes which require high energy input in initial or middle oven zones. Products bake quicker in higher airflow ovens due to the greater temperature increase per minute at the product core level. Subsequently, relevant thermal events, such as yeast kill, starch gelatinization and arrival, occur sooner when tracked by an S-curve.

Velocity of the circulating air also influences baking time. The higher the air velocity, the faster the product loses moisture and the sooner the crust forms. Weight loss, browning of crust, and firmness of baked product can be increased by increasing air velocity. For example, increasing air velocity results in drier products with a darker crust color. High-speed ovens have mechanisms which control the flow of air, these are often referred to as color-aiders.

Application

Ovens are designed to offer an even distribution of air velocity across the baking chamber or oven band / conveyor. Even distribution of airflow is vital to maintain the quality of product delivered by convection ovens. Side-to-side airflow variation is directly related to side-to-side variation in product bake. An uneven flow of air within the chamber often leads to differences in product volume (e.g. some loaves are larger than others), variations in crust color and other quality issues.

Modern high-speed bread, cracker and cookie ovens rely heavily on air to transfer heat to the product. In most cases, the contribution of convective heat flux represents values as high as 80% of the total heat transfer; the other 20% are in the form of radiant and conductive heat.

How to measure oven air velocity

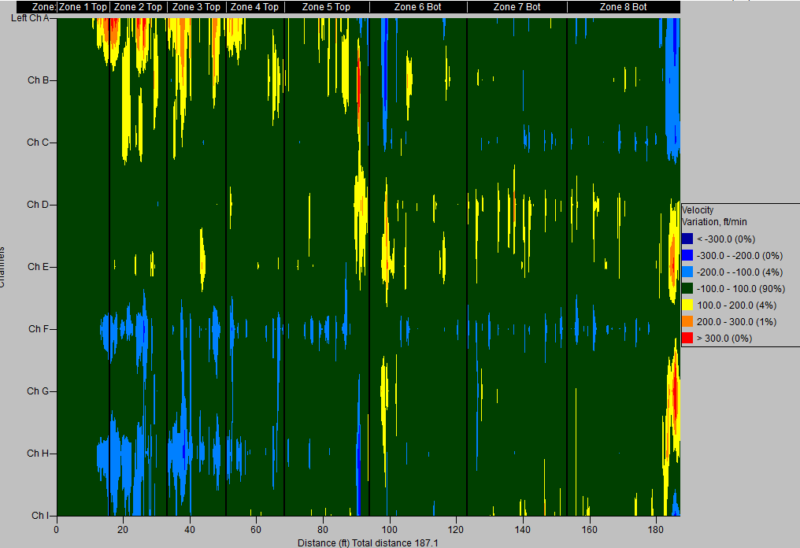

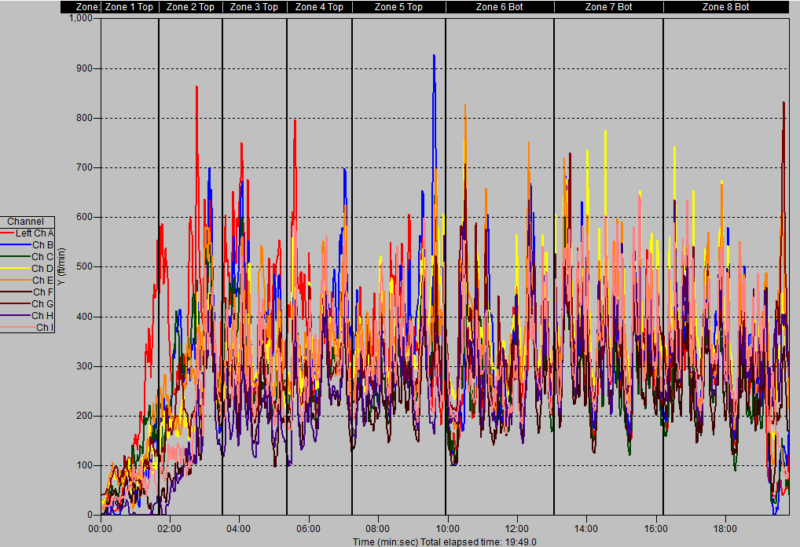

Oven air velocity can be recorded by an air velocity sensor. Arrays of sensors can provide a precise picture of airflow patterns inside an oven from side to side and end to end. These sensors collect data, at product level, as the array passes through the process. The number of sensors required vary with the width of the conveyor.

Air velocity sensor arrays can help with spotting airflow differences between baking zones, concentrated air velocities on isolated parts of the conveyor, and unwanted air currents at the entrance or exit of the oven.

Here is an example for bread:

Air velocity profiles are useful in adjusting your process to maximize quality and reduce waste. The tighter the pattern of lines, the more even the air distribution is across the width of the process. By measuring air velocity design engineers are able to balance heat and airflow across the width and along the length of the process oven.

References

- Sluimer, P. “Baking and Cooling.” Principles of Breadmaking: Functionality of Raw Materials and Process Steps, American Association of Cereal Chemists, Inc., 2005, pp. 139–164.

- Purlis, E. “Heat and Mass Transfer during Baking.” Advances in Heat Transfer Unit Operations: Baking and Freezing in Bread Making, CRC Press, Taylor & Francis Group, LLC, 2017, pp. 173–188.