Oven Heat Flux

Also known as flow of heat during baking

What is Oven Heat Flux?

Heat flux is one of five critical parameters in baking operations. It is defined as the amount of energy transferred per unit area per unit time from or to the product surface and is expressed in Btu/hr.ft2, J/S.m2 or W/m2.

Three components constitute oven heat flux. Their ratios can influence the quality of baked products:

- Radiation

- Convection

- Conduction

How it works

It is important to recognize that different products have their unique mix of heat flux components. Therefore, they’ll have their own heat flux profile.

Knowing the total heat experienced by the product, and the contribution of individual heat fluxes is critical to understanding finished product characteristics. This information helps explain why one oven bakes differently from another. Analyzing and controlling these aspects are fundamental to product quality.

Heat flux by radiation

It occurs between two surfaces or materials at different temperatures by the emission of energy in the form of electromagnetic waves and subsequent absorption. Heating elements and oven walls emit energy in the form of electromagnetic waves. The energy flux (Q) depends mainly on the temperature of the object.

According to Stefan–Boltzmann’s law, heat flux radiation to the dough is proportional to the difference between baking chamber wall temperature (TW) to the power of four and dough temperature (TD) to the power of four:1,2

![]()

Where:

- σ is the Stefan–Boltzmann constant, 5.67 x 10-8 W/(m2·K4)

- T is temperature (in Kelvin units)

- ε is the emissivity of the object (typically between 0 and 1)

Heat flux by convection

It represents the heat transferred by means of a moving fluid, like hot air in the baking chamber. Natural or forced convection is a function of flow characteristics. For example, the absence of of fans, blowers and other air-movement devices like color-aiders.3

Forced convection devices recirculate the air and/or combustion gases surrounding the product to provide driving force to maintain as high heat transfer as possible (i.e. the temperature difference between hot air and product).3

Heat flux by convection can be calculated as:1,2

![]()

Where:

- h is the convective heat transfer coefficient (in W/m2·K)

- A is the area (in m2)

The h coefficient depends on oven conditions, product geometry and air properties, mainly:

- Air velocity

- Air viscosity

- Thermal conductivity of air

- Specific heat of air

- Air temperature

- Product geometry

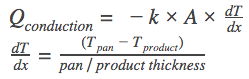

Heat flux by conduction

Transfer of heat to a dough or batter by conduction occurs at the dough surface level in a baking pan (or tin). Or, at the interface between the oven hearth and the dough piece when the product is placed directly onto the hearth. According to Fourier’s law, the heat flux by conduction is deduced from the following formula:1,2

Where:

- k is the thermal conductivity of air, pan or dough (in W/m·K)

- A is the area of the pan or product through heat flows (m2)

- dT/dx is the temperature gradient between to points (in the case of pan bread baking, these two points can be the pan and dough)

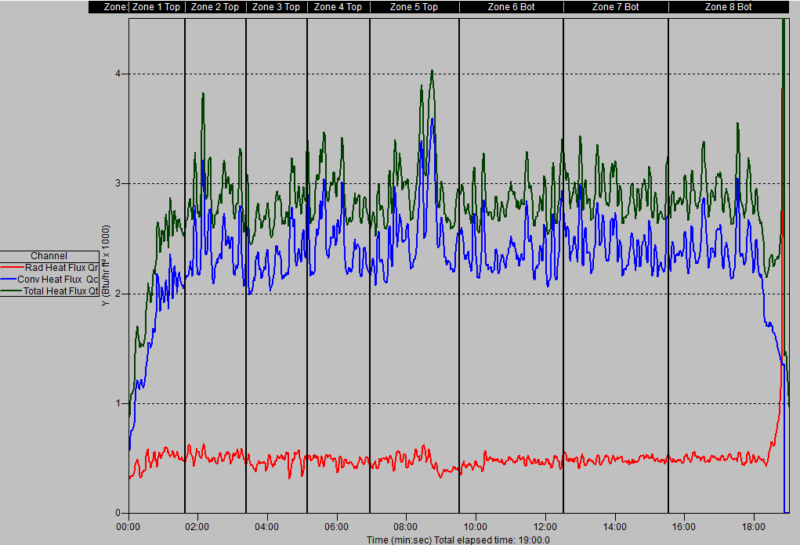

Application

In pan bread production, convective and radiant heat is absorbed by the pan, which also serves as the mechanism to conduct heat to the product. Product specific characteristics are defined by the amount of energy and the combination of heating mechanisms used to bake the product in a given oven.

Heat flux profiles are often used when trying to produce the same product on two different lines, or when transferring product from one line to another. Matching the heat flux component profiles ensures consistency in baking on both lines.

![]()

Oven heat flux is rarely monitored or controlled on a real-time basis in a routine high-speed baking. However, it is essential for the oven design phase and prior to equipment onsite commissioning.

How is heat flux measured?

The heat flux sensor is designed to measure convective and radiant heat fluxes at the product level, and to identify which modes of heat transfer are predominant:

References

- Sluimer, P. “Baking and Cooling.” Principles of Breadmaking: Functionality of Raw Materials and Process Steps, American Association of Cereal Chemists, Inc., 2005, pp. 139–164.

- Singh, R.P., and Heldman, D. “Heat Transfer in Food Processing.” Introduction to Food Engineering, 4th Edition, Academic Press, Elsevier Inc., 2009, pp. 247–401.

- Purlis, E. “Heat and Mass Transfer during Baking.” Advances in Heat Transfer Unit Operations: Baking and Freezing in Bread Making, CRC Press, Taylor & Francis Group, LLC, 2017, pp. 173–188.