Optimize Your Donut Production

When it comes to donut production, optimizing your production process is key to reducing waste and improving your margins. An optimized process results in high-quality donuts. Bakeries of all sizes benefit from a robust quality assurance program. It makes a significant difference in product consistency and customer satisfaction. Join us as we share some insights from our recent Donut BAKERview on advanced quality control techniques.

Optimize Your Process Now!

To maintain proper donut quality, bakers must focus on several key factors throughout the production process. Consistent ingredient quality is crucial, as variations can affect dough texture and taste. Optimizing your mixing, proofing, and frying times and temperatures ensures uniformity in size, shape, and color. Utilizing advanced stabilizer solutions also helps maintain structural integrity and prevent issues such as cracking and weeping. Continuous monitoring and data collection allow for immediate adjustments to maintain optimal conditions. Additionally, proper storage and handling, including managing freeze/thaw cycles, are crucial to preserving the fresh, appealing appearance and texture of the final product.

Donuts Pocket Guide

Key Aspects of Donut Production Quality Control

Real-Time Quality Monitoring

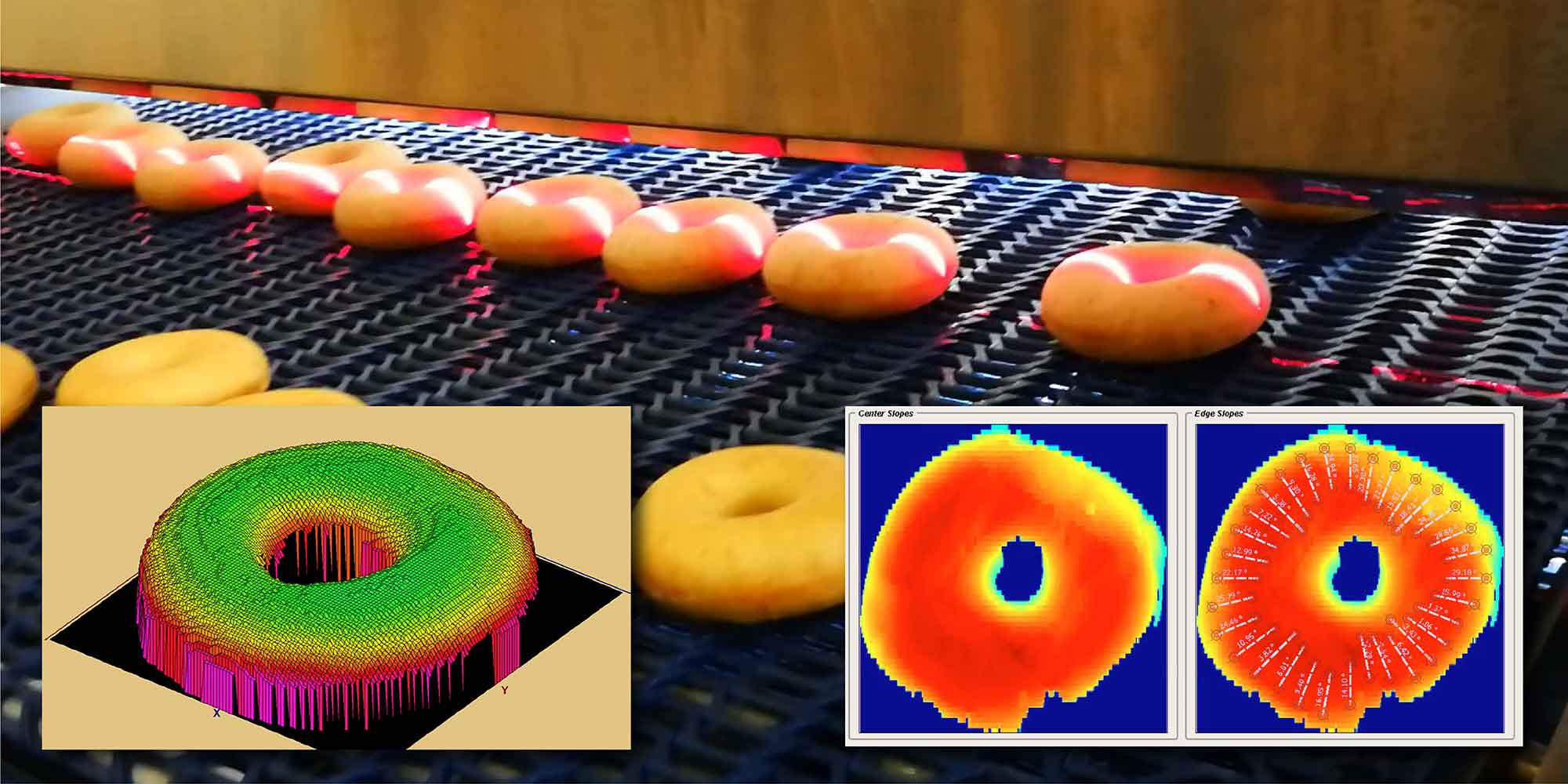

Traditional quality assurance methods often involve periodic sampling and manual analysis, which can be time-consuming and prone to variability. Typically, bakers might weigh samples, use calipers, or conduct sensory tests to evaluate texture and appearance. However, these methods do not provide real-time insights or automation capabilities.

In-Line and Over-Line Vision Inspection technologies provide 100% visual inspection of product at full-line speeds.

Advanced Vision Systems

KPM Analytics introduces state-of-the-art vision systems to revolutionize quality monitoring. Utilizing 3D profile cameras with laser lines, these systems capture detailed profiles of each product. For instance, on a donut production line, the laser scans each donut, creating a comprehensive 3D image. This allows for precise monitoring of product dimensions and surface characteristics, ensuring uniformity and quality.

Bottom-Side Inspection

An innovative feature of KPM’s system is the ability to inspect the underside of products. This is crucial for detecting issues like foreign objects or imperfections that might not be visible from the top. Inconsistent baking or frying can lead to defects on the bottom side, and this inspection capability ensures such defects are identified and rectified before packaging.

Data-Driven Decision Making

A significant advantage of KPM Analytics’ systems is the data collection and analysis capabilities. The systems generate detailed data on every product, providing insights into the production process. This data includes key measurements and histograms showing process variability, which are essential for continuous improvement.

Artificial Intelligence Integration

The integration of artificial intelligence (AI) in quality control systems marks a leap forward. The AI learns from the collected data, making intelligent adjustments to the production process. For example, if the system detects a color deviation in the donuts, it can decide whether to hold the current settings or make gradual changes to rectify the issue without overcompensating.

Donut Production Process Control

Forming and Sheeting

Consistent thickness is critical during the dough forming and sheeting stages. KPM Analytics offers 3D systems that measure the dough thickness in real-time, identifying deviations that could affect the final product. If the dough is too thick or thin, the system can alert operators or automatically adjust the sheeting rollers, maintaining optimal dough consistency.

Baking and Frying Adjustments

Additionally, KPM’s technology extends to baking and frying processes. The system monitors color and texture, making real-time adjustments to baking temperatures and times. This ensures that donuts are uniformly baked, preventing issues like uneven coloration or undercooking.

Ingredient Solutions for Delicious Donuts

In the quest for optimizing your donut production, achieving consistent quality and texture is paramount. Advanced stabilizer solutions from Vantage Food, such as Stabligel Plus, Stabilite Icing Stabilizer, Perma-Frost, and RTU Stabilizer, can help address common issues faced by industrial bakers. These specialized formulations not only improve the overall quality of donuts but also streamline production processes, ensuring that the final products meet high standards of excellence.

Stabligel Plus

Stabligel Plus is a concentrated stabilizer solution tailored for snack cakes, honey buns, and other baked or fried applications. For donut production, it helps maintain the structural integrity of the dough during frying and baking. This results in donuts that have a uniform shape, an appealing texture, and a longer shelf life. By stabilizing the dough, Stabligel Plus ensures that each batch of donuts has consistent quality, reducing the likelihood of defects and waste.

Stabilite Icing Stabilizer

One of the key challenges in donut production is managing the quality of glazes and icings, especially under freeze/thaw conditions. Stabilite Icing Stabilizer is specifically formulated to address this issue. It prevents the glaze from cracking or separating when frozen and thawed, ensuring that donuts retain their glossy, appealing finish. This stabilizer is particularly beneficial for products that require storage before reaching the consumer, as it maintains the visual and textural quality of the icing, enhancing the overall customer experience.

Perma-Frost

Perma-Frost is a super-concentrated powdered stabilizer designed for donuts and honey buns. It effectively prevents cracking, separation, and weeping of glazes and fillings, which are common issues that can detract from the quality of the final product. By incorporating Perma-Frost into the production process, bakers can ensure that donuts remain visually appealing and structurally sound, even under varying storage and handling conditions. This stabilizer is essential for maintaining the fresh, appetizing appearance that customers expect from premium donut products.

RTU Stabilizer

The RTU (Ready-to-Use) Stabilizer is an excellent solution for icings and glazes that need to perform well under reheated conditions. It prevents cracking, separation, and weeping, ensuring that donuts maintain their quality after reheating. This is particularly useful for bakeries that offer ready-to-use icings and glazes, as it provides flexibility in production and distribution. By using RTU Stabilizer, bakers can deliver donuts that consistently meet quality standards, regardless of when they are consumed.

Curious to learn more? Watch the BAKERview here:

For bakers today, adopting these advanced systems and ingredient solutions not only safeguards product quality but also paves the way for a more streamlined and efficient production process. Real-time monitoring, automated adjustments, and comprehensive data analysis ensure consistent product quality, reduce waste, and improve operational efficiency. As the baking industry evolves, leveraging such innovative technologies is essential for staying competitive and meeting customer expectations.

Want to stay up-to-date with BAKERpedia? Sign up for our newsletter today!