Bread Evaluation

What is Bread Evaluation?

Bread evaluation is a systematic, subjective and semi-quantitative method for scoring bread products relative to a standard which is usually defined by the bakery’s R&D and QC departments.

- It is different from objective product evaluation, which is based on the measurement of variables and analysis of factual data.

- Bread scoring is based on sensory evaluation of its internal and external characteristics.

How does it work?

The first step the bakery should work on is having a standard as the base for bread evaluation if proper bread evaluation is to be done. Setting a standard of what is an ideal bread can be done by:

- Benchmarking best production practices

- Looking at competitor’s bread and finding improvement opportunities

- Carrying out consumer research and receiving feedback from customers

- Performing bake tests or lab trials (looking for perfection)

The characteristics of bread are divided into internal (related to the crumb) and external (outside surface of baked loaf including caramelization or dehydration during baking).

| Internal | External |

|

|

A “standard bread” product that has an optimum combination of volume, external and internal characteristics should be the base for comparison when performing bread scoring.

Procedure for bread evaluation1

| When to score | Sample selection | Sample preparation | Method and order of evaluation | Who scores |

|

Bread evaluation should be done at least once per shift (per variety). Bread can be scored the same day of production or within 2 days of baking. |

Samples should be selected randomly from each production run of each variety, ideally on a daily basis. Selected samples should be representative of the batch. Samples can also be taken from the market. |

Loaves must be completely cool before scoring. A warm crumb can tear or collapse during slicing. Once properly cooled, the loaves should be sealed in plastic bags and kept at room temperature in a storage cabinet until scoring. |

|

Properly trained personnel and may include:

|

Application

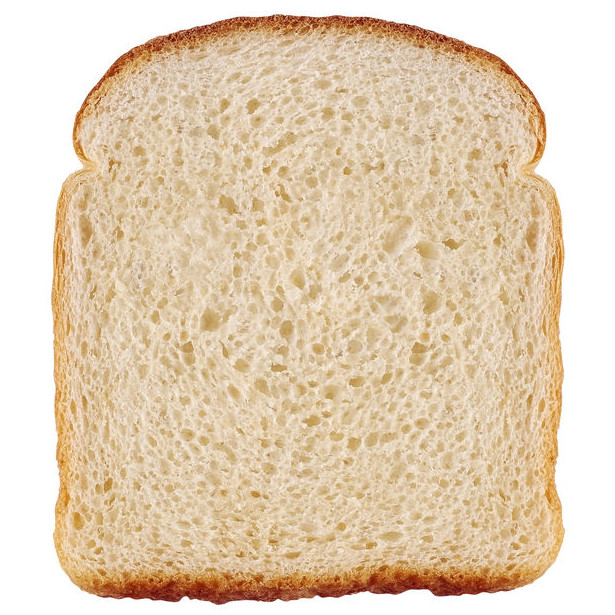

Every bread has its own requirements and quality characteristics. The quality of bread is a function of its ingredients, yeast activity and processing conditions. The soft and resilient texture and fine cell structure (grain) of a slice of white pan or whole wheat bread, are features that consumers expect when purchasing these breads.

An “ideal” or high-quality loaf of white pan bread should have the following characteristics:

| Internal | External |

|

|

The following scoring model can be used to compare bread samples against the standard. Any deviations from optimal characteristics, either insufficient or excessive, should be penalized with a lower score.

| Highest score | Average score | Lowest score | |

| Bread characteristic (internal or external) | 10 | 5 | 1 |

| Relation to standard | Closest | Half-way | Farthest |

A score sheet form is usually filled out during a bread evaluation process. Such form can look like this:

| SCORE SHEET FORM | |||

| Sample or dough No. | |||

| 1 | 2 | 3 | |

| Loaf volume | |||

| Break and shred | |||

| Symmetry | |||

| Crust color | |||

| Crust surface | |||

| Comments external characteristics | |||

| Subtotal external score (E) | |||

| Grain | |||

| Crumb color | |||

| Flavor | |||

| Aroma | |||

| Tactile crumb texture | |||

| Mouthfeel | |||

| Comments internal characteristics | |||

| Subtotal internal score (I) | |||

| Total (E + I) | |||

References

- AACC International. Approved Methods of Analysis, 11th Ed. Method 10–12.01. Guidelines for Scoring Experimental Bread. Final approval September, 2012. Cereals & Grains Association, St. Paul, MN, U.S.A.