Maltose

Also known as malt sugar, maltobiose or 4-alpha-D-glucopyranosido-D-glucopyranose

What is maltose?

Maltose is a disaccharide made up of 2 glucose units. It is a reducing sugar, so it contributes to Maillard browning and caramelization reactions. In baking, maltose is used as a substitute for sucrose and is a good yeast nutrient.¹

Maltose can be found as a crystalline solid or as a syrup.¹ Commercially, malt syrup is available in 3 versions based on dextrose equivalent (DE):

- High maltose syrup (DE 35–50, 45–60% maltose)

- Extra high maltose syrup (DE 45–60, 70–85% maltose)

- High conversion syrup (DE 60–70, 30–47% maltose)

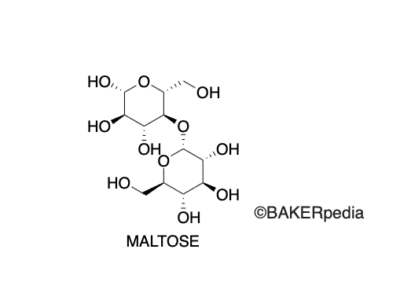

Chemical Structure

Origin

Maltose is obtained from the hydrolysis of starch or through grain malting mainly barley. It is not commonly found in nature, except in some plants due to starch hydrolysis.¹

Maltose was first isolated in 1819 by Saussure from the enzymatic reaction with malt diastase.

Function

Maltose has several functions in baking:¹

- Sweetness: provides a sweet taste although to a lesser degree than fructose, sucrose and glucose.

- Tenderizing: interferes with gluten formation, protein coagulation, and starch gelatinization, and thus delays structure formation.

- Moistness: a result of its hygroscopic nature.

- Shelf life improvement: can extend the shelf life of baked goods by preventing moisture loss and staling.

- Browning: contributes to browning of baked goods via Maillard reaction as well as caramelization reactions. Maltose has the slowest browning rate of all common sugars.

- Leavening: only its crystalline form contributes to leavening.

- Nutrient for yeast fermentation. It helps with slow fermentation, aiding adequate gassing in the final proofing stages.

- Flavoring: provides a distinctive flavor especially the syrup form.

Nutrition

Maltose contributes 4 calories per gram. Sugars in general contribute to several health problems like obesity, increase of blood pressure and high glucose concentration in blood.²

One drawback of maltose is its high glycemic index (GI = 105), the highest of all common sugars.²

Commercial production

Maltose syrup in commercially produced though the following process:³

- Slurry production: starchy material such as rice or corn powder are mixed with water in a mixing tank followed by enzyme addition.

- Liquefaction: the mix is liquified at high temperatures.

- Deproteinization: the slurry is filtered to remove residual protein.

- Saccharification: the liquefied material is added to the saccharification tank with the enzyme (β-amylase) for reaction.

- Decolorization: maltose syrup is decolorized with activated carbon.

- Filtration: the activated carbon is removed through a filter press.

- Ion exchange: cations and anions removal.

- Concentration and evaporation: the syrup is evaporated under vacuum, cooled and stored.

Application

Maltose can be used as a substitute for sucrose in several baked goods formulations.

Considerations when using maltose:¹

- It has a milder sweetening effect compared to sucrose, and thus the dose of maltose should be increased in relation with sucrose.

- To substitute granulated sugar with syrup, divide the mass of sucrose by 0.80 and reduce the amount of liquid by the difference of the two.

Benefits of maltose usage in baked goods:¹

- Improves yeast fermentation, particularly during the later proofing stages.

- Adds sheen to bagels when incorporated into the boiling water.

- Provides a characteristic flavor to baked products.

- Provides a lesser degree of browning than other common reducing sugars.

Regulations

The FDA considers maltose GRAS and can be used without any limitation except GMP’s.4

In the EU, maltose is also considered a safe substance for use in food products.5

References

- Figoni, P. How Baking Works: Exploring The Fundamentals Of Baking Science. 2nd ed., John Wiley & Sons, Inc., 2008.

- Qi, Xin, and Richard F. Tester. “Lactose, Maltose, and Sucrose in Health and Disease.” Molecular Nutrition & Food Research 64.8 (2020): 1901082.

- “Maltose Syrup Manufacturing Process Solution-Maltose Syrup Processing Technology Business Plan”. Syrupmachinery.Com, 2020, https://www.syrupmachinery.com/solutions/#:~:text=Maltose%20syrup%20process%20machine%20technology%20description%3A&text=Mixing%20slurry%20unit%20during%20the,transported%20to%20next%20work%20section. Accessed 9 Oct 2020.

- “Substances Added To Food (Formerly EAFUS)”. Cfsanappsexternal.Fda.Gov, 2020, https://www.cfsanappsexternal.fda.gov/scripts/fdcc/index.cfm?set=FoodSubstances&id=MALTOSE. Accessed 9 Oct 2020.

- “Maltose – Substance Information – ECHA”. Echa.Europa.Eu, 2020, https://echa.europa.eu/nl/substance-information/-/substanceinfo/100.000.651. Accessed 9 Oct 2020.