Emulsifiers

What are Emulsifiers?

Emulsifiers are surface-active ingredients that stabilize non-homogeneous mixes, like water and oil.1,2 When water and oil exist in a system, the oil eventually separates and floats to the top. To stop this, emulsifiers are used as an intermediary for water and oil.

Various emulsifiers are used in foods and bakery formulas. Some common examples are lecithin, mono- and di-glycerides, DATEM, SSL and CSL. Examples of stabilized emulsions include:

- Milk, a complex mixture of fat suspended in an aqueous solution

- Cake batters

- Icings and glazes

- Butter/Margarine

Origin

Historically, food systems have relied on egg yolks and soy phospholipids as emulsifiers. Commercial emulsifiers were introduced to the food industry in the 1930s in the form of mono- and di-glycerides.

Function

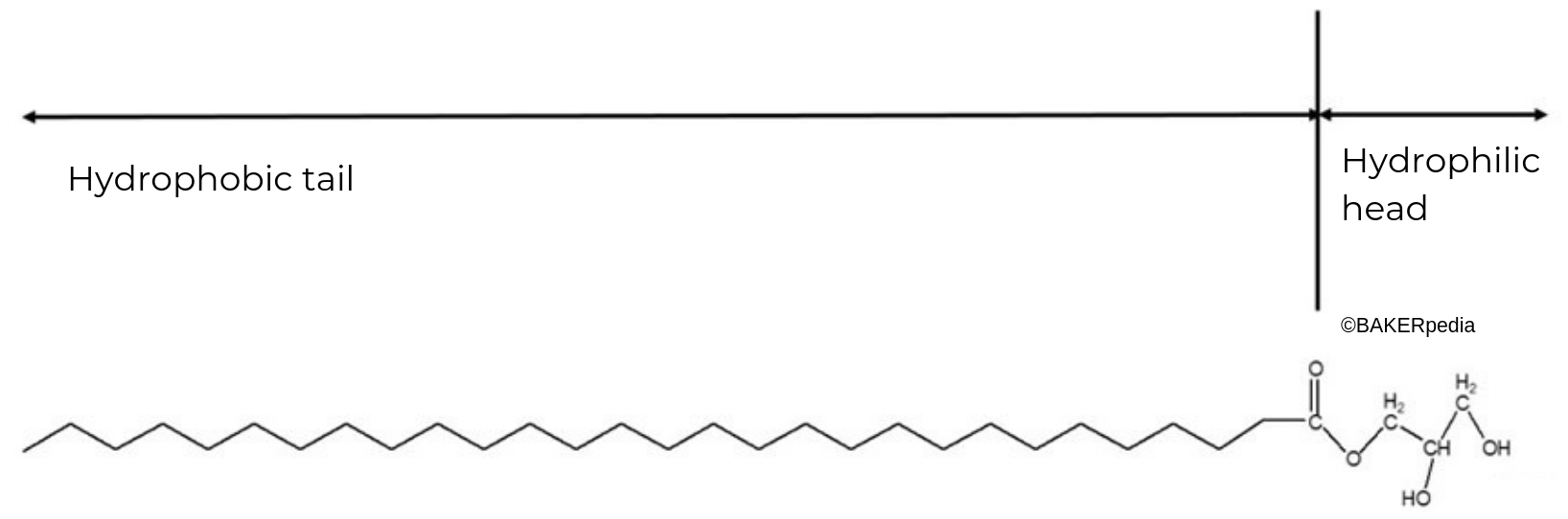

An emulsifier’s functionality is based on the presence of lipophilic (lipid-loving) and hydrophilic (water-loving) moieties or regions. These bind to nonpolar and aqueous groups, like the image below:

Another important property is their hydrophilic-lipophilic balance (HLB). This is an indication of the size and strength of the emulsifier’s regions. HLB typically ranges from 0–20. Zero is entirely an lipophilic molecule, while 20 represents an entirely hydrophilic one.

In bakery products, emulsifiers help with:2,3

- Batter stabilization

- Enhancement of batter aeration or creaming

- Crumb softening or shelf-life extension by reducing the rate of starch retrogradation

- Dough strengthening for better gas retention and optimum product volume

In chemically-leavened, batter-based products

Sweet goods such as layer cakes and muffin batters are achieved by emulsifiers keeping water and oil together, reducing the surface tension.1

In yeast-leavened products

Breads and buns use emulsifiers to help with crumb softening and to reduce staling. Also, they can help with dough strengthening by promoting aggregation and cross-linking of gluten-forming proteins. Products formulated with emulsifiers have superior dough handling properties, higher gas retention capacity for better volume, and extended shelf-life.1,3

Emulsifiers that function as dough strengtheners or crumb softeners:

| Dough strengtheners (HLB > 10) | Crumb softeners (HLB < 10) |

[fusion_separator style_type=”default” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” sep_color=”#ffffff” top_margin=”5″ bottom_margin=”10″ border_size=”” icon=”” icon_circle=”” icon_circle_color=”” width=”” alignment=”center”][/fusion_separator]

Commercial production

They can be produced from fats and oils, or fatty acids with glycerin using a variety of techniques:

- Direct esterification

- Interesterification

- Glycerolysis with lipase

Application

The following table shows characteristics, application, usage and special considerations for some common emulsifiers:

| Emulsifier | HLB | Amount used (based on flour weight) | Application/considerations |

| DATEM | 8–10 | 0.1%–0.5% |

|

| Mono- and di-glycerides | 2.8–3.5 | 0.5%–2.0% |

|

| Lecithin | 8–10 | 0.5%–2.0% |

|

FDA regulation

Emulsifiers are regulated by the FDA in the United States. The following table summarizes emulsifiers’ maximum amount permitted by the Agency:2,4,5

| Emulsifier | Legal limit |

| Stearoyl Lactylates (SSL, CSL) | 0.5% based on flour |

| Polysorbate 60 in cakes | 0.46% of cake mix |

| Polysorbate 60 in yeast-leavened baked goods | 0.5% of flour |

| Mono- and di-glycerides | GRAS (limited only by current GMPs) |

| DATEM | GRAS (limited only by current GMPs) |

| Lecithin | GRAS (limited only by current GMPs) |

| Sorbitan monostearate | 0.61% of cake mix |

| Succinylated monoglycerides | 0.5% based on flour |

References

- Stauffer, C.E. Emulsifiers, Eagan Press Handbook Series, AACC International, Inc., 1991, pp. 1–101.

- Finnie, S., and Atwell, W.A. Wheat Flour Handbook, 2nd Edition, AACC International, Inc., 2016, pp. 91–159.

- De Leyn, I. “Other Functional Additives.” Bakery Products Science and Technology, 2nd edition, John Wiley & Sons, Ltd., 2014, pp. 299–305.

- U.S. Food and Drug Administration. “21 CFR 172 – Food Additives Permitted for Direct Addition to Food for Human Consumption.” 1 Apr. 2018,https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=172. Accessed 7 July 2019.

- U.S. Food and Drug Administration. “21 CFR 184 – Direct Food Substances Affirmed As Generally Recognized As Safe.” 1 Apr. 2017, https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=184. Accessed 2 December 2018.