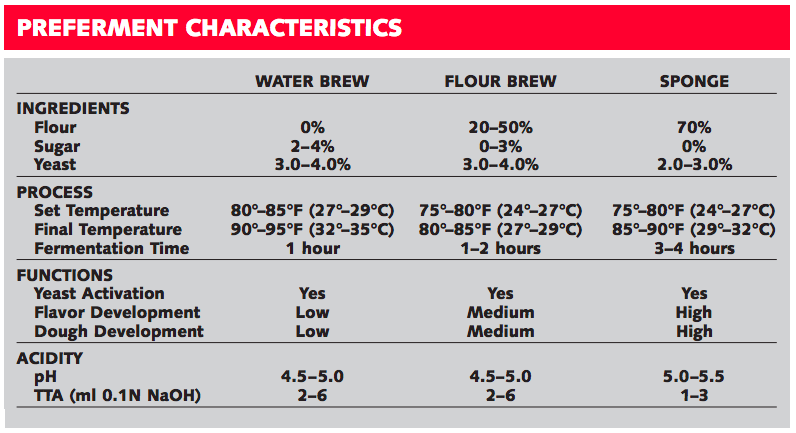

Preferment is the general term for the sponge or brew step that is used at the start of many bread making processes. There are three basic types of preferments made with commercial bakers yeast that are most used by industrial bakers:

- Sponge or “plastic” preferment: usually contains about 70 percent of the total dough flour and ferments in a trough for three to four hours

- Flour brew or liquid sponge: usually contains about 20 to 50 percent of the total dough flour and ferments in a tank for one to two hours

- Water-brew or flour-free ferment: usually contains sugar instead of flour and ferments in a tank for about an hour.

However, all preferments have the same key roles:

- Yeast Activation

- Flavor Contribution

- Dough Development

Let’s look at these more closely.

Yeast Activation

Commercial baker’s yeast is made up of dormant yeast cells that go through a lag phase before producing carbon dioxide gas at their highest rate. The preferment minimizes the lag phase by providing an optimum environment for the yeast. The result is higher gas production later in the process, especially in high-sugar doughs. Yeast activation can be monitored in the laboratory by counting budding yeast cells or by measuring gas production, and in the bakery by checking final proof times and loaf volumes.

Yeast activation takes place during the first thirty to sixty minutes in all types of preferments. Longer preferment times are not necessary for yeast activation and can have a negative effect because yeast starts to lose activity once the available sugar has been consumed. The only reason for longer preferments is for flavor contribution or dough development.

Flavor Contribution

Bread taste and flavor precursors are produced in the preferment mostly by the yeast. In short preferments inoculated with only commercial bakers yeast, the low levels of bacteria present in the yeast and flour do not have much of an effect. The precursors include alcohols and organic acids that react with other compounds during baking and contribute to the taste and flavor of the finished product. The flavor contributed by water-brew systems is minimal and increases with the amount of flour present in flour brew and sponge systems.

Flavor contribution can be monitored by measuring the TTA (total titratable acidity) in the preferment—the higher the TTA, the more flavor. The optimum TTA depends on the product, and higher levels can cause a sour off-flavor. TTA and flavor contribution in the preferment can be controlled by varying the time, temperature, and ingredient factors that affect yeast activation.

Dough Development

Dough development in the preferment is important because it affects the mixing, consistency, and gas retention of the final dough, which in turn affect the volume, texture, and overall quality of the finished product. The preferment affects dough development mostly by lowering the pH, which activates proteases and other naturally-occurring enzymes in the flour. Proteases break down gluten irreversibly. Proteases also decrease mix time, increase elasticity, and can improve gas retention, but with a trade-off for less tolerance.

It is also affected by the water in the preferment hydrating the starch and gluten, and by the physical and chemical effects of the alcohol, carbon dioxide, and organic acids.

Dough development in the final dough depends on mixing, the oxidation system, and the preferment. The amount of dough development in the preferment depends mostly on time, pH, and the amount of flour—the longer the time, the lower the pH, and the more flour, the greater the dough development. The dough development contribution in water-brew systems is minimal and increases with the amount of flour present in flour-brew and sponge systems. Dough development is usually controlled by varying the preferment time. It can also be decreased by adding salt to reduce the fermentation rate and lessen the amount of gluten hydration.

How to Optimize your Preferment

Optimizing the preferment for a given breadmaking system can require trade-offs because fermentation affects gas production, flavor contribution, and dough development at the same time but not in the same way. In practice, dough development usually takes precedence.

Optimizing dough development means matching gas retention to gas production in the proofed dough when it is put into the oven. A well-developed dough is dry, pliable, and retains gas well to produce a large volume with a fine grain. Underdeveloped dough is tough, rubbery, and lacks the extensibility needed to retain gas well. Overdeveloped dough is wet, stringy, and lacks the strength needed to retain gas well.

Here are some recommendations for optimizing preferments, with an emphasis on the factors that affect dough development:

- Time and temperature: To increase dough development, increase preferment time and temperature. To decrease dough development, decrease preferment time and temperature. A minimum of thirty to sixty minutes is enough for yeast activation. Generally, a longer prefermentation time contributes to better flavor.

- Ingredients: To increase dough development, remove salt and add flour, yeast, yeast food, and sugar. To decrease dough development, add salt and reduce flour, yeast, yeast food, and sugar. Use acid yeast food only if the water is alkaline. More flour in the preferment usually contributes to better flavor.

- Yeast addition point: Adding yeast to the preferment increases yeast activation, flavor contribution, and dough development. Adding yeast, or “spiking,” at the dough side shortens the final proof time, which decreases flavor contribution and dough development.

The role of pH and TTA: the secret to fermentation

Measuring pH and TTA

Bakers measure pH and total titratable acidity (TTA) to monitor the progress of fermentation in a preferment. There is a correlation between fermentation and acidity because the yeast and bacteria in a preferment produce carbonic and other weak acids. When a simple acid (shown here as HA) dissolves in water, it dissociates into a hydrogen ion or proton (H+) and an anion (A–) according to this general reaction:

HA fi H+ + A–

Strong acids dissociate completely into hydrogen ions and anions, but weak acids dissociate only partially, and not all of the acid molecules generate hydrogen ions. pH measures hydrogen ion concentration and so gives a good indication of strong acid concentration but a poor indication of weak acid concentration.

When an acid (HA) and a base (BOH) are mixed together in water, they neutralize each other to form a salt (AB) and water (H2O) according to this general reaction:

HA + BOH fi AB + H2O

The amount of strong base required to neutralize an acid depends on the amount of acid, not its strength. This is the basis for the TTA determination, where, in one method, a 10-gram sample is diluted in 50 milliliters of water, then neutralized with 4-gram-per-liter (1 N) sodium hydroxide (NaOH) to pH 6.6. The resulting TTA value is expressed as milliliters of NaOH. Other methods use different sample sizes, NaOH concentrations, or conversion factors.

Preferment pH starts at 5 to 6, decreases with time, and eventually levels off. pH is important because it affects many of the processes taking place in dough. Lower pH decreases carbon dioxide solubility and increases the effectiveness of preservatives like calcium propionate. The optimum is 4.2 for gluten swelling and 5 to 6 for yeast activity.

Preferment TTA starts below 1 and increases with time. TTA is a better indicator of fermentation activity than is pH, because it continues to increase after pH levels off.

Monitoring fermentation progress is important when optimizing the effects of preferments on yeast activity, flavor contribution, and dough development. The graph (right) shows a 50-percent flour preferment, where yeast activity peaks at about 1 hour, pH levels off after about 2.5 hours, and TTA continues to increase beyond 3 hours. If the optimum fermentation activity was at 2 hours, the optimum TTA would be 2. This value can be used to standardize the results with other preferments even if time and temperatures vary.