Nixtamalization

Also known as alkaline- or lime-cooking of maize

What is Nixtamalization?

Nixtamalization is the process of masa preparation that involves cooking whole corn in water containing lime (alkali), steeping and washing, and then followed by grinding and drying the resulting nixtamal to masa flour.

Masa is used in the production of various maize-derived goods such as corn tortillas, corn chips, tortilla chips, tacos, etc. Nixtamalization is considered one of the three value-added processes of maize processing:

- Dry milling

- Wet milling

- Nixtamalization or lime cooking

Origin

The nixtamalization method as a means to produce food was developed by ancient Mesoamericans. Pre-Columbian indigenous civilizations such as the Aztecs and Mayans found in this process the key for their development.1,2

In the traditional process, maize is lime-cooked in clay pots over a fire, followed by overnight steeping. The resulting nixtamal is washed by hand and milled into a “masa” (Spanish word for dough) with a stone grinder named metate.1,2

The ancient manual nixtamalization process has now been adapted to high-speed manufacturing methods aimed towards the production of large volumes that serve growing markets around the world.

How it works

The nixtamalization process is used to make masa dough and masa flour (ground, dried and sifted masa dough).

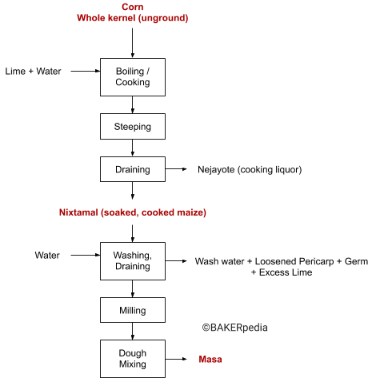

The following block diagram shows the steps of the nixtamalization process:

Processing specifications

- Lime / calcium hydroxide Ca(OH)2: 0.5–1.5% based on corn weight. Calcium oxide CaO can be used instead of lime (CaO in the presence of water produces calcium hydroxide).

- Water: 150.0–300.0% (Lb / 100 Lb maize) based on corn weight

- Boiling at atmospheric conditions (non-pressurized): 0.5–3.0 hours at 176–212°F (80–100°C)

- Steeping: 8–24 hours at 131–149°F (55–65°C)

- Washing and draining of nixtamal: step is repeated several times until sufficient lime solution and kernel components have been removed.

Application

The basic ingredients used in the nixtamalization process are maize kernels, lime, and water. Shelf life extension and improved nutritional value of masa dough or dry masa can be achieved via incorporating ingredients such as gums, emulsifiers, acidulants, preservatives and vitamin premixes.

Nixtamalization process causes physicochemical changes in the flour. Significant changes in corn starch glass transition temperatures are often found during the cooking and steeping phases of the nixtamalization process and kernel hydration and subsequent softening.

This process can also increase the concentration of resistant starch in nixtamalized corn flour, a potentially beneficial attribute for ‘low glycemic’ formulations.

Specifications for maize

Maize intended for nixtamalization should meet the following criteria:2,3

- Kernel size should be intermediate to large (1000-kernel weight of 11.3 oz or 320 g)

- Test weight of 72 kg/hL

- Density of 1.3 g/cm3

Kernel hardness, density, and test weight are key parameters as they are intimately related to dry-matter loss and product yield (Kg masa / 100 Kg maize).

Kernels with a soft texture cook faster but break easily during storage, transport and processing. It is expected that the pericarp be easily removed during nixtamalization. Hard kernels can take longer to cook and do not absorb enough water after normal processing times.

Typical kernels water absorption is about 30% during cooking and an additional 15% during steeping. This phenomenon is closely related to the degree of starch gelatinization. A high-quality maize should tolerate overcooking and abuse during handling and industrial manufacturing.

Lime solution

Lime addition facilitates pericarp removal during cooking and steeping, controls microbial activity through pH, affects texture, flavor, aroma, color, shelf life, and nutritional value. This becomes evident when eating corn tortillas and flour tortillas which have a distinct “strong” flavor and aroma.2,3

This weak alkali can also enhance the bioavailability of calcium and improves niacin bioavailability but may negatively affect other nutrients due to leaching (solubilization) of phenolics, organic acids, antioxidants (carotenoids) and B-vitamins (water-soluble) into the steep or wastewater commonly known as nejayote.2,3

Loss of corn solids during nextamilization is considered an economic as well as wastewater disposal problems.

References

- Serna-Saldivar, S.O. “Maize: Foods from Maize.” Encyclopedia of Food Grains, 2nd edition, Volume 3: Grain-Based Products and their Processing, Academic Press, Elsevier Ltd., 2016, pp. 106–108.

- Serna-Saldivar, S.O. “Milling of Maize into Lime-Cooked Products.” Cereal Grains: Properties, Processing, and Nutritional Attributes, CRC Press, Taylor & Francis Group, LLC, 2010, pp. 239–254.

- Serna-Saldivar, S.O. “Industrial Production of Maize Tortillas and Snacks.” Wheat Flour and Corn Products, Cereals and Grains Association, AACC International, Inc., 2016, pp. 247–278.