Distillers Grain Bread

Also known as brewers or spent grain bread

What is Distillers Grain Bread?

Distillers grain bread is a yeast-leavened bakery product made from a combination of bread flour (patent) and distillers or brewers dried grain flour.

Similar to whole wheat or rye bread, it is a fiber-rich product that has a unique flavor, aroma and texture.

Origin

The production of distillers and brewers grains is growing around the globe. This is due to the rapid growth and/or expansion of beverage distilleries and craft breweries in the United States, Europe and other parts of the world.

As a consequence, higher amounts of these materials are generated everyday and their use in bakery and cereal products (e.g. muffins, bread, rolls, pasta and cookies) is becoming more widespread.1

How does it work?

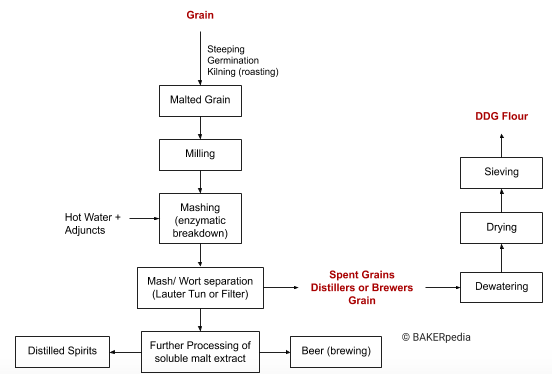

During the fermentation of sprouted cereals (e.g. barley, corn, rye and wheat) for the manufacture of distilled spirits, beer and others, starch is converted to alcohol, organic acids and carbon dioxide, while the non-fermentable components (e.g. proteins, fiber, fats, vitamins and minerals) remain in the residue. This wet by-product known as spent malt grain has superior digestibility, due to enzymatic breakdown, and can be processed and turned into distillers dried grain (DDG) flour.1

Chemical Composition of DDG

The composition of DDGs depends on the type of cereal used and the processing conditions employed at the distillery or brewery. DDGs are generally rich in protein and dietary fiber, very low in simple carbohydrates, with a dark yellow or brown color. Here is a block diagram of the production process of DDG flour:

Formulation of bread with DDG

Distillers grain bread can be produced with different dough systems. The straight dough process being preferred by larger production facilities.

The following formulation uses the straight dough process:

| Ingredient | Baker’s % (based on flour weight) |

| Bread flour (patent)* | 90.0–80.0 |

| (DDG) flour** | 10.0–20.0 |

| Sugar (granulated, refined sucrose) | 3.0–8.0 |

| Salt | 1.5–2.2 |

| Non-diastatic malt (optional) | 0.0–2.0 |

| Nonfat dry milk | 2.0–4.0 |

| Shortening (all purpose) | 1.5–3.0 |

| Yeast (compressed) | 2.5–5.0 |

| Water | 60.0–70.0 |

| Dough conditioner mix | 1.0–4.0 |

| Vital wheat gluten | 1.5–5.0 |

* Protein content 12.5–14.0%, ash content 0.45–0.55% (depending on flour extraction and wheat class).

** Product from the milling and particle size standardization (sieving) of DDG.

Processing

The production of distillers grain bread follows similar processing to white pan bread or variety bread. The main differences in processing are found in the makeup stage.

Processing steps:

- Ingredient scaling/metering.

- DDG soaking (pre-hydration): given its high fiber content, it is recommended to pre-hydrate the DDG flour with a portion of total water prior to dough mixing.

- Dough mixing: mix for 30 seconds on first speed, then on second speed to full gluten development. Desired temperature of dough after mixing is 75–82°F (24–28°C).

- Makeup. More gentle stress forces and strain should be applied during dividing, rounding and moulding (less tight sheeter, pressure board and guide rails settings).

- Panning.

- Final proofing: 92–95˚F (33–35˚C); 85% RH for 30–40 min. The higher the inclusion of DDG, the shorter the proofing time.

- Scoring/topping (optional).

- Baking: bake at 400–420°F (204–216°C) to an internal temperature of 204°F (95°C). The higher the inclusion of DDG, the lower the oven temperature and the longer the bake time.

- Depanning.

- Cooling: Cool baked goods to an internal temperature of 90–95°F (32–35°C).

- Slicing.

- Packaging or serving.

Application

- The absence of gluten-forming proteins and very high fiber content of DDG limit the amount of this ingredient that can be incorporated into the bread dough. Typically inclusion levels should not exceed 15–20%.

- Dilution of gluten proteins due to the presence of fiber and non-functional flours (flours that do not contain gluten-forming proteins) must be compensated for with vital wheat gluten to ensure proper gluten matrix development with good handling properties.

- DDG can also be used in the production of high-fiber bread. Adjustments in formulation are required for labeling compliance.

As a rule of thumb, High inclusion levels of DDG can affect various aspects of dough processing and baked bread as summarized below:2

| Dough processing | Finished Product |

|

|

References

- Rosentrater, K.A., and Evers, A.D. “Bread-baking Technology.” Kent’s Technology of Cereals. An Introduction for Students of Food Science and Agriculture, 5th edition, Woodhead Publishing, Elsevier Ltd., 2018, pp. 614–615.

- Brochetti, D., et al. Yeast Bread Containing Distillers’ Dried Grain: Dough Development and Bread Quality. Journal of Food Quality. 1991;14:331–344.