Struggling with Mold? Sanitation Can Help!

Mold issues? Here’s a Novel Way to Increase the Shelf Life of Your Product!

If you’re experiencing mold or yeast contamination within a few days after your product is baked, you might have high mold and yeast counts on your cooling conveyor belt. Bakery products are mold and yeast-free from the oven, where internal temperatures reach over 87.8°C (190°F). However, they can be contaminated with mold and yeast during the cooling stage. This could come from excessive mold spores in the air or from the cooling conveyor belts. While mold spores can be significantly removed through flour reclaim systems and air filters, how does one have ample downtime to regularly clean and sanitize cooling belts?

Today’s high-output bakeries require high-speed solutions for cleaning and sanitizing their production lines due to the increasing demand for convenient and ready-to-eat products. Each downtime minute counts and must be expended consciously. Novel cleaning and sanitization trends answer the industry demands by offering solutions that can improve the overall process efficiency while maintaining the quality of the products consumers request. But how do they affect the shelf life of your baked goods?

A Sanitized Surface Extends Shelf Life

Surface sanitation isn’t just for effective allergen cleanup. It is an essential part of the production process of any bakery or food industry facility. Guaranteeing the optimal cleaning of working surfaces significantly reduces microbial counts that will reduce or eliminate product loss while improving the overall process and reducing downtime of production lines.

Food products come in contact with various surfaces that may carry potentially harmful pathogens or contaminants that may cause food safety recalls. Production equipment, conveyor belts, and other food-contact surfaces all represent potential risk surfaces for contamination. Thus, sanitation represents one of the most critical challenges to confront by industry quality professionals.

Contamination of finished products due to an ineffective sanitation program is a major concern of food safety experts worldwide. It is extremely important to find production equipment with an appropriate hygienic design and then choose sanitation methods and techniques to effectively and consistently clean and sanitize that equipment at the appropriate intervals.

The solutions needed by a bakery may differ from those needed by a meat or fresh vegetable producer. In addition to the ingredients, restricting certain sanitation alternatives may be allowed in certain industries while prohibited in others.

Finally, as mentioned above, it’s extremely important to consider the type of surface to be cleaned, especially if it has many cavities or cracks where food components may be deposited and could be challenging to remove. With these factors in mind, a clearer image of the sanitation solution your operation may require comes into focus. However, more precautions may need to be taken into consideration, if you are looking to comply with certain bakery trends.

A Clean-label and Organic Approach

According to the CODEX Alimentarius in their General Principles of Food Hygiene, appropriate sanitation begins with adequate hygienic design. Food facilities must first consider using non-toxic materials for their intended use, which must be durable and easy to sanitize and maintain. Non-toxic means materials that, when in contact with food products, may not react to produce harmful substances or components. This also considers the cleaning of sanitation substances that may come in contact with the equipment and thus needs to be innocuous when applying sanitation techniques.

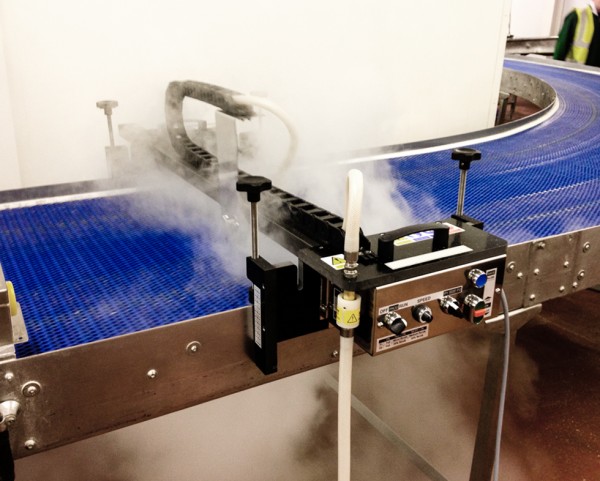

Conveyor Belt Sanitizer from Goodway Technologies

The surfaces must be easy to clean, meaning they must not have unnecessary cracks or cavities that may represent potential deposit centers of contaminants. Materials recommended for equipment that comes into contact with food products range from stainless steel and aluminum to plastic and rubber.

Conventional methods of surface sanitation use in the food industry can be classified into the following categories:

1. Wet-cleaning methods

Wet cleaning is a thorough method that employs copious amounts of water, detergents, and sanitizers to effectively eliminate soil and microorganisms from surfaces. It’s particularly suited for environments with liquid-intensive production processes or where stubborn residues need to be tackled, ensuring a high level of cleanliness.

The process described involves extensive use of water and cleaning solutions, frequently incorporating rinsing, scrubbing, and soaking. It is appropriate for environments with adequate drainage and water-resistant equipment, such as dairy processing, brewing, and other high-moisture food production areas. While this method is effective, it has high water and energy consumption. It poses risks such as water damage to sensitive equipment and potential microbial growth if surfaces are not dried properly.

2. Semi-dry cleaning

Semi-dry cleaning strikes the perfect balance by using minimal water and other cleaning agents to ensure effective results while conserving water. It’s ideal for areas where a bit of moisture is fine, but too much water could cause issues, making it a smart choice for efficient and safe cleaning.

This cleaning method uses minimal water, often paired with foams or gels, making it effective for moderate soils that don’t necessitate heavy washing. It includes techniques like wiping, spot cleaning, or low-moisture steam cleaning and is ideal for equipment and areas that can handle some moisture but must stay relatively dry. Compared to wet cleaning, it reduces water and energy usage and poses a lower risk of water damage to equipment. While it still requires some drying time, it is significantly less than wet cleaning.

3. Dry cleaning

Dry cleaning methods completely avoid using water, relying on mechanical actions, vacuuming, compressed air, and specialized dry-cleaning agents. This approach is crucial in environments where strict moisture control is necessary to avoid contamination or damage to products and equipment, ensuring a pristine and safe workspace.

In addition, dry cleaning methods like vacuuming, brushing, scraping, and using absorbent powders or chemical cleaners are ideal for environments where even small amounts of moisture can be problematic, such as bakeries, confectioneries, and certain packaging areas. This approach eliminates the risk of water damage and microbial growth associated with moisture, making it suitable for sensitive equipment and areas.

Discover the Best Sanitation Solution for Your Bakery

Proper sanitation processes are vital to ensuring the quality of your baked goods and the efficiency of your production in the long run. Innovative sanitization methods, including wet, semi-dry, and dry cleaning, can be easily adapted to fit your production lines and scale. For more assistance with your sanitation services, contact Goodway Technologies. Learn more about Goodway Technologies’ sanitation solutions here!

References

- Holah, John, H. L. M. Lelieveld, and Domagoj Gabric, eds. Handbook of hygiene control in the food industry. Woodhead Publishing, 2016.

- Lelieveld, Huub LM, and Yasmine Motarjemi, eds. Food safety management: A practical guide for the food industry. Academic Press, 2013.

- Pakdel, Mahsa, Anna Olsen, and Eirin Marie Skjøndal Bar.”A Review of Food Contaminants and Their Pathways Within Food Processing Facilities Using Open Food Processing Equipment” Journal of Food Protection 86.12 (2023): 100184.

Want to stay up-to-date with BAKERpedia? Sign up for our newsletter today!