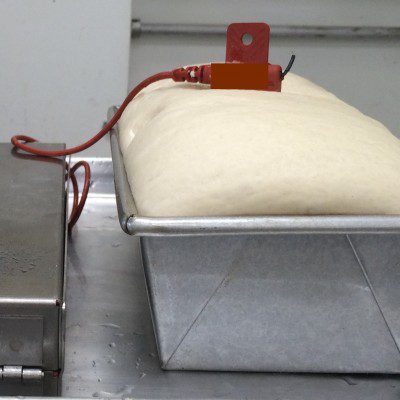

Thermocouples are inserted into dough to give a thermal profile.

Why?

Because it gives you quality and consistent products. A thermal profile reads and analyzes the change of temperature inside a product while it is baking in the oven. It will give you the whole picture of what is happening to your product the whole time, not just a snapshot of one time (like a thermometer reading when you take the product out of the oven).

How much is the “whole picture?”

Commercial ovens have multiple zones of control, each of which can be measured by thermal profiling. Here are three main sections of the baking cycle:

- Oven Spring: This must be manipulated to reach a yeast kill by 50% of the baking cycle. A fast yeast kill means the production of carbon dioxide is cut off, so there is less oven spring. Optimizing yeast kill will give you more control over the height of the product.

- Critical Change: This zone is important to release water and prepare the crumb to set. It’s where your dough turns into delicious bread.

- Crumb Set: This one is all about the texture. Increasing time in this zone will dry up the crumb of your product.

All three steps can be measured and then properly adjusted when you use a thermal profile. Thermocouples are inserted into dough or batter throughout the baking process, and the resulting data can be logged and/or transferred for you to analyze.

What targets should you reach? Find out on the thermal profiling page.