Cocoa Fiber CO is a preparation obtained from roasted cocoa hulls by cleaning, micronization and sterilization (heat-steam). The process is only physical and does not involve any chemical treatment, making the product 100% natural. And the color, taste and aroma characteristics of cocoa powder are preserved.

The preparation can be used as a component for bakery and other products. Cocoa Fiber CO may replace up to 100% of cocoa powder at any ratio, depending on the cocoa powder color. Normally, fiber usage also requires extra water addition to achieve consistency typical of final product without fiber.

How do products with cocoa fiber turn out?

At InterFiber, as a producer of natural food fiber, we did some testing with our cocoa fiber CO product. Our research was run on extreme values: 100% cocoa fiber compared to 100% cocoa powder. Also, we referred to a defatted cocoa which is a typical product on the Polish market.

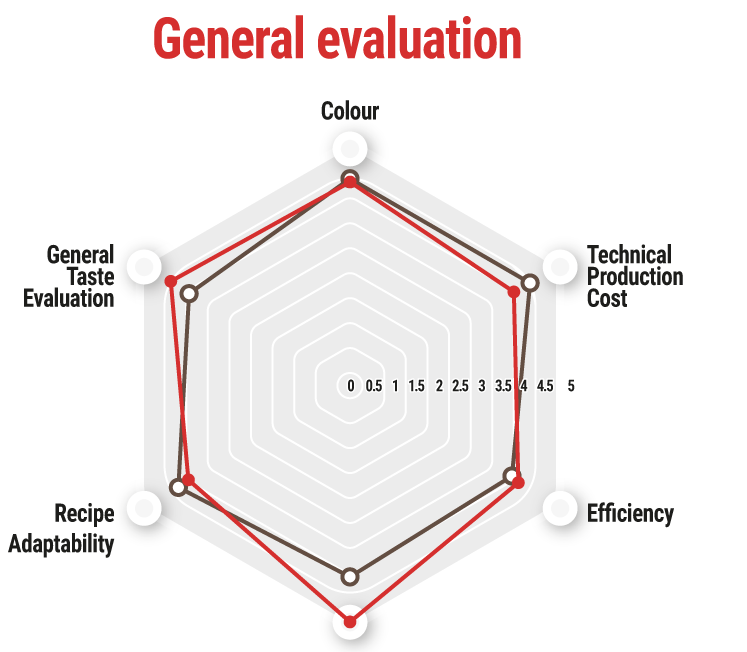

We ran a series of blind tests on muffin application on a panel consisting of 20 people. Their task was to compare and assess the two muffins with and without fiber addition, taking into account different parameters. The results in average were the following:

Here’s what we found out:

- No difference in color was noticed

- The cocoa fiber sample was evaluated as tasting better

- Crumb color and structure were assessed as similar

- Cocoa fiber provides better homogeneity and deliquescence

- Cocoa fiber gained a higher general rating

- Efficiency and adaptability are on an equal level for both cocoa fiber and powder samples

- Total production cost is generally lower for cocoa fiber

Cocoa Fiber CO from InterFiber.

What needs to be taken into consideration is the fact that there are different types of cocoa powder available on the global market. Every one of them can be replaced with our product but with different results. According to our research, approximately 20% of the darkest and the most expensive cocoa powder can be replaced with our cocoa fiber. The lighter the color of cocoa powder is, the higher the ratio can be. However, it needs to be remembered that it is not always possible to replace cocoa powder with cocoa fiber because of the legislative reasons in definite product categories.

Using our fiber in the final product will increase fiber content and, in specific cases, it is even possible to achieve the quantity of fiber necessary for source of fiber declaration.

Have you found Cocoa Fiber CO interesting? Contact us for more details!