Aspects of Staling

Crumb firming is caused by changes in starch structure. The starch in wheat flour is made up of straight and branched chains contained in granules. During baking the starch granules swell and the straight chains diffuse out. Then, as the bread cools, the straight chains link together to provide the loaf’s initial shape and strength. The branched chains of starch remain in the granules during baking and link together slowly during storage to make the crumb increasingly firmer with time.

- Moisture changes: contribute to staling through evaporation and water redistribution. Evaporation can cause a 10 percent weight loss in unwrapped bread but usually less than 1 percent in wrapped bread. Even when its moisture level doesn’t change, wrapped bread tastes dry because water has migrated from the crumb to the crust and from the starch to the gluten.

- Crust softening: in wrapped bread is caused by an increase in moisture from about 12 to 28 percent. This changes the dry, crisp, pleasant texture of fresh crust into the soft, leathery, unpleasant texture of stale crust.

- Flavor losses and changes occur as some flavor components diminish faster than others. The taste of fresh bread is usually a combination of sweet, salty, and slightly sour, but with age the sweet and the salty diminish and the remaining sourness starts to become unpleasant. The aroma of fresh bread is usually yeasty and wheaty, but with age the pleasant alcohol smell of yeast is lost, the wheaty odor is reduced, and the remaining doughy or starchy aromas become unpleasant.

Factors Affecting Bread Staling

Ingredients affect crumb firming and moisture changes:

- Fats slow staling by improving loaf volume.

- Sweeteners slow staling directly by retaining moisture, and most other ingredients that increase absorption usually inhibit staling.

- High-protein flours improve crumb softness by contributing to a larger loaf volume, as do many other ingredients that increase loaf volume.

Processing

This affects initial crumb softness through loaf volume. In particular, fermentation and mixing that provide optimum dough development for a given flour will maximize volume and crumb softness. Water absorption and baking procedures change the moisture levels of the crumb. Slack doughs, along with optimum proofing and oven temperatures, maximize absorption and reduce staling.

Packaging

Packaging affects moisture changes, crust texture, and flavor. Unwrapped bread loses moisture and flavor faster, but retains crumb texture better. Wrapped bread stays softer (especially when wrapped warm) and tastes better (especially when wrapped cool), but the crust softens faster. Temperature affects all aspects of staling. Crumb firming is fastest at low temperatures, between 20° and 50°F (–5° and 10°C). And high temperatures, above 95°F (35°C), affect color and flavor, so 70° to 95°F (20° to 35°C) is the optimum storage temperature range for bread. Freezing at 0° to –20°F (–20° to –30°C) has the effect of about one day’s storage time, but then effectively stops all aspects of staling indefinitely. The crumb-firming effects of staling can be reversed by briefly heating to 120°F (50°C) or more, but is less effective when done a second or third time.

Emulsifiers (surfactants)

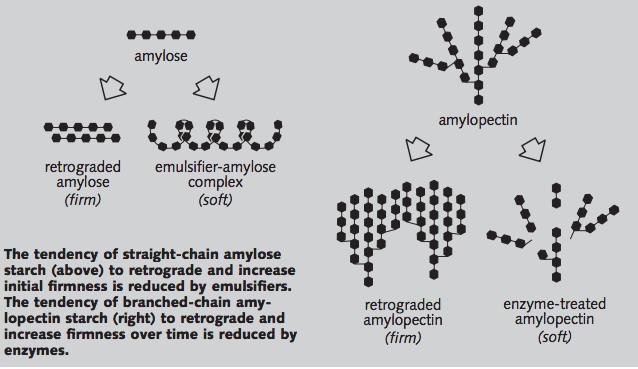

These are used as antistaling agents, mostly because they increase initial softness. They combine with the straight-chain starch inside the starch granules and keep it from diffusing out so that it doesn’t contribute as much strength to the initial crumb set. Emulsifiers do not have as much effect on the branched starch that causes crumb firming during storage and do not slow the moisture migration from crumb to crust. Emulsifiers are used as both dough strengtheners and crumb softeners. Those used primarily as softeners include mono- and diglycerides, distilled monoglycerides, polysorbate 60, and sodium stearoyl lactylate (SSL).

Enzymes (alpha-amylases)

These are used as antistaling agents because they slow the rate of crumb firming in a way that may also slow the rate of moisture migration. Enzymes break down a portion of the starch during processing and baking, so it does not cause as much firmness when it links together during storage. The temperature stability and action pattern of the enzymes are important so that enough branched starch is broken down to inhibit staling, but not so much that the crumb becomes sticky and difficult to slice.

Measuring Staling

Consumer testing, crumbliness, and water absorption are sometimes used to measure bread staling, but the most common method is compressibility. The most common compressibility measurements use one of these four instruments:

- Instron Universal Testing Machine

- Baker Compressimeter

- Bloom Gelometer

- Voland Stevens Texture Analyzer

Comparing results from the different instruments and methods is difficult, and they all measure compressibility by pressing slices flat instead of squeezing at the sides as consumers do. But when used properly, the compressibility measurements give a good indication of how consumers will perceive differences in bread staling rates.

A typical method for the Voland Stevens LFRA Texture Analyzer measures the pressure required (in grams) for a one-inch plunger moving at 2 mm per second to compress a one-inch bread slice 10 mm. In a typical staling experiment, bread is stored in plastic bags at room temperature for one, three, and five days. Then five measurements are taken on each of two slices cut from the center of the loaf. The ten measurements are averaged to give a firmness value for each day. The graph shown here illustrates the typical difference between a control and samples treated with emulsifiers or enzymes.

Starch Chemistry

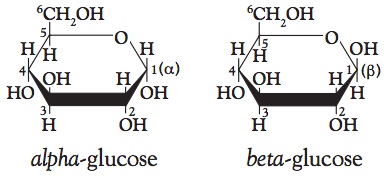

D-glucose is the basic building block of starch. Its chemical model is a hexagon made up of one oxygen atom, five carbon atoms (numbered 1 through 5), and two forms (alpha- and beta-) depending on its structure at position 1:

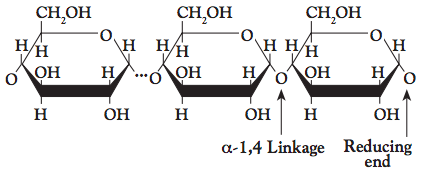

Starch is made up of linear and branched polymers of D-glucose. The linear amylose portion is made up of thousands of glucose units connected by alpha-1,4 linkages:

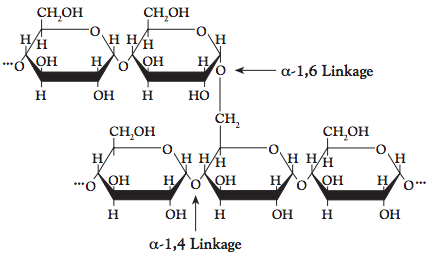

The branched amylopectin portion of starch is made up of a million or more glucose units in groups of twenty to thirty each and connected at branch points by alpha-1,6 linkages:

The granules that make up the starch in wheat flour contain approximately 25 percent amylose and 75 percent amylopectin. Although amylose and amylopectin are both made up of the same D-glucose building block, they have different chemical and physical properties that affect their behavior during baking.

- Amylose readily diffuses out of starch granules when they hydrate and swell (gelatinize) at about 140°F (60°C). It complexes readily with emulsifiers and can be broken down almost completely into maltose sugar by beta-amylase. Amylose recrystallizes, or retrogrades, rapidly when it cools after gelatinization.

- Amylopectin does not readily diffuse out of starch granules when they gelatinize, and it complexes little if at all with emulsifiers. It is not affected much by beta-amylase because of its alpha-1,6 linkages but can be broken down into smaller dextrins with shorter branches by alpha-amylase. Amylopectin retrogrades slowly upon cooling after gelatinization and contributes to increased firmness because of its larger size and three dimensional linking.

How Starch Affects Firming