Process Design

Also known as process development

What is Process Design?

Process design refers to the organization and configuration of food and chemical processes and manufacturing methods needed to transform/convert raw materials into finished products. Such processes are a sequence of events and steps directed to a specific result.1,2

Processes and manufacturing methods vary according to the composition and nature of ingredients and finished products. Process design takes into account:1,2

- Unit operations

- Transport phenomena

- Process engineering and control

- Process economics

- Food safety laws and regulations

How does it work?

Process design focuses on developing a means to manufacture a food product such as baked goods in a given quantity or volume. It involves the selection and sequencing of process steps known by process engineers as unit operations. The purpose of process design is to meet the needs of an industrial plant for economic, smart and sustainable production of goods.

Process design begins with a well-defined product, often available in prototype quantities from research labs. It is intimately related to product and plant design and demand the application of engineering principles and techniques in addition to practical experience.

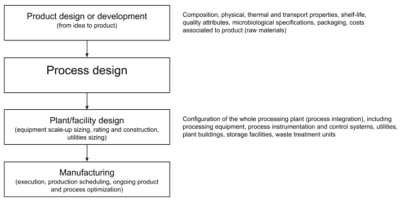

The following diagram is an illustration of typical process design:3,4,5

Several tasks are involved in process design which require skilled multidisciplinary teams known as design teams. These teams may be include electrical, civil, chemical, food, mechanical and control engineers.

Tasks/steps of process design:1,5

- Process flowsheeting for required production, examples include process control diagrams (PCD), process flow diagrams (PFD), process instrumentation and piping diagrams (PID)

- Identification of unit operations (specific to the plant process requirements)

- Material and energy (heat) balance (engineering data)

- Sizing and rating of the required industrial process equipment

- Capacity analysis

- Cost of equipment (capital and operational) and utilities

- Techno-economic, financial and profitability analysis

- Parametric optimization

- Environmental analysis

Application

Unit operations are classified according to the type of transport phenomena and belong namely to:

- Mass transfer

- Energy (heat) transfer

- Momentum transfer operations

A unit operation may imply a physical or chemical modification:

- Physical modification: size reduction, sieving, mixing, pumping, pneumatic conveying, mechanical conveying, sedimentation, filtration, heating (e.g. baking, frying, extrusion, pasteurization, evaporation, distillation, hot drying), cooling (e.g. refrigeration, blast freezing, freeze-drying).

- Chemical modification (involves chemical reactions that render new products): fermentation, neutralization, browning, enzymatic processing, malting.

Some operations involve simultaneous heat and mass transfer, one example is oven baking of bakery products.

Process flowsheeting

Choosing the best process configuration requires building a clear process flowsheet. It is a “plant model” of all process streams, equipment, control systems, transport/conveying systems, by-product streams and waste streams.

A simple example of this could be the location of a heat source (e.g. boiler for production of saturated steam that is needed in a proof box) and a point of heat/moisture evacuation (e.g. exhaust/venting systems).

Material and energy balances

Once process flowsheeting and determination of unit operations have been completed, material and energy balances become essential for process design. No process stream and its respective flow rates or amounts (e.g. tons/batch, pounds/second) can be determined without prior performance of material and energy balances.

Product composition and related engineering data (physical, thermal and transport properties) are needed to complete material and energy balances. The amount of materials and heat used is key for the following stages such as process costing and equipment design.

Material and energy balances can be carried out using process modeling and simulation tools. Such software tools simulate what could be happening in a real manufacturing plant with after all processes have been integrated.

Access to required unit operations, composition data banks for pure components and stock mixtures, possibility to schedule operations, use of real process parameters and engineering data, are all necessary for an accurate and realistic execution of material and energy balances.

References

- Maroulis, Z.B., and Saravacos, G.D. “Principles of Food Process Design.” Food Process Design, Marcel Dekker, Inc., 2003, pp. 37–87.

- Rahman, M.S., and Ahmed, J. “Food Process Design: Overview.” Handbook of Food Process Design, Blackwell Publishing Ltd., 2012, pp. 18–23.

- Purlis, E. “Baking Process Design.” Handbook of Food Process Design, Blackwell Publishing Ltd., 2012, pp. 743–765.

- Clark, J.P. “Process and Equipment Selection.” Practical Design, Construction and Operation of Food Facilities, Academic Press, Elsevier Inc., 2009, pp. 85–122.

- Seider, W.D. “Introduction to Process Design.” Product and Process Design Principles: Synthesis, Analysis and Evaluation, 4th edition, John Wiley & Sons, Inc., 2017, pp. 19–45.