Falling Number Test

What is the falling number (FN) test?

The Hagberg Falling Number test, originally developed in Sweden, is used to measure the enzyme activity in flour. The FN of a flour is related to the amount and activity of cereal enzyme α-amylase, which is present in the wheat after harvesting. Wheat kernels with high moisture levels usually exhibit high levels of α-amylase.

The FN is used in the baking industry for assessing:

- Sprout damage in wheat kernels

- Enzymatic activity in wheat flour

- Crop-year changeovers and selection of wheat flour suppliers

- Its effect on water absorption (water binding capacity)

- Machinability and dough-handling issues of dough during processing

- Upgrades/establishment of specifications for flours at receipt (e.g., starch damage, enzymatic activity)

How does it work?

The FN test details the effect of the α-amylase on the starch granules in the flour undergoing gelatinization, and progressively broken down (cleaved) by the amylase action.1 The temperature set for the test provides maximum enzymatic activity in the flour/water mixture or suspension.

The FN is the time in seconds required for a device to fall a measured distance through a hot flour/water mixture while heat is applied. If the enzymatic activity is high, the starch is broken down (liquefied) rapidly during gelatinization. So then, the device falls through the relatively liquid paste in a short time. A less viscous fluid opposing less resistance to the flow means the FN is low. On the other hand, if the activity of the enzyme is low, it takes longer for the device to cover the distance of its fall. This means the falling number is high.2

Application

Falling numbers over 250 seconds are most suitable for the bread-baking process. In contrast, FNs above 350 seconds may indicate that the flour should be supplemented with a form of amylolytic enzyme or with malted grain flours.

Most large-scale bakeries work with an ideal FN range of 250–280 seconds. Different values of fall numbers may be specific to unique products and processing conditions inside the plant.1

As a rule of thumb for most bakeries, the higher the amylase level, the greater formation of dextrins during breadmaking. This results in a sticky dough that is not only difficult to handle, but has slicing issues as well.

Steps for FN analysis3

- Prepare/weigh a representative amount of sample (usually 250–350 g of dry product).

- Place the flour into the viscometer tube.

- Specify the moisture content of the flour (use correction table).

- Using a dispenser/pipette, pour distilled or tap water (approximately 25 mL) into the viscometer tube.

- Thoroughly shake the flour/water mixture in the viscometer tube until a homogeneous suspension is obtained (this step can be performed by a shaking device).

- Place/insert the viscometric tube with the stirring rod in a warm bath at boiling temperature.

- Start the FN instrument. After 5 seconds, the agitation will start automatically.

- After a few seconds the stirring rod is automatically released in its upper position and starts to fall.

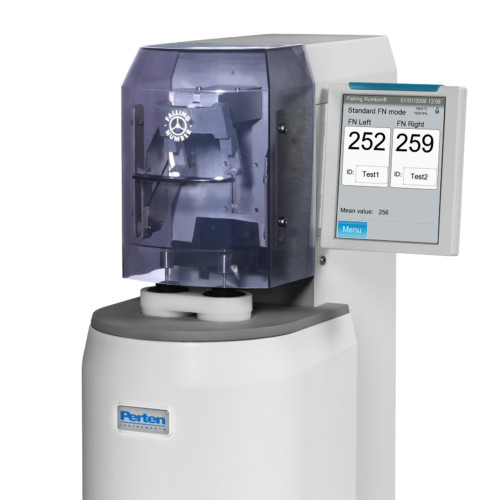

- The total time, in seconds, from the moment the device is activated until the rod descends a certain distance is registered by the equipment. This is the FN.

Approved methods to measure FN of cereal flours

- AACC International Method 56-81.03 (Determination of Falling Number)

- ICC Standard No. 107/1 (Measurement of the degree of α-amylase activity in grain and flour (according to Hagberg-Perten)

Please note that both methods are identical.

References

- Cauvain, S.P. “Raw Materials.” Baking Problems Solved, 2nd ed., Elsevier Ltd., 2017, pp. 58–59.

- AACC International Method 56–81.03 (Physicochemical Tests). “Determination of Falling Number.”

- Perten Instruments. “The Falling Number® Method.” https://www.perten.com/Products/Falling-Number/The-Falling-Number-Method/. Accessed 5 March 2018.