Polyglycerol Esters

Also Known as PGEs

What are Polyglycerol Esters?

Polyglycerol esters of fatty acids (PGEs) are used in food as an emulsifier. PGEs are a class of synthetic, nonionic surfactant frequently used in food, pharmaceutical, and cosmetic industries on account of their amphiphilic properties. The hydrophilic part of these amphiphiles consists of oligomeric esters of glycerol, and the hydrophobic part consists of alkyl chains of varying length and degree of unsaturation.1

In foods, they are used as emulsifying agents in the production of baked goods, chewing gum, and in replacement of fats.

Origin

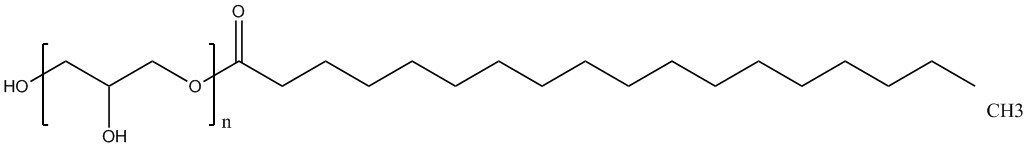

PGEs have been used as food additives in Europe and America since the 1940s and they were approved for food use in the U.S. in the 1960s.2 Figure 1 is the structure for polyglycerol monoester.

Figure 1: Structure of polyglycerol monoester1

Commercial Production

PGEs are produced by polymerization of glycerol in the presence of an alkaline catalyst followed by esterification with fatty acids.1 The fatty acids are from corn oil, cottonseed oil, lard, palm oil, peanut oil, sesame oil, sunflower oil, soybean oil, etc.3 Besides esters, PGEs also contain impurities, like mono, di, and triglycerides, free fatty acids, free glycerol and polyglycerol, and sodium salts of fatty acids may be present.

Function

Components of bakery products, such as oil, water and flour, are not soluble in each other. Interfaces are present between these substances, such as water and oil, gases (air bubbles) and solid substances (flour components), air and water. PGEs, like other emulsifiers, have both a hydrophobic and hydrophilic nature so they can reduce interfacial tension between different phases.

PGEs’ hydrophilic-lipophilic balance (HLB) depends on the length of the polyglycerol chain and the degree of esterification. The HLB can vary from 3 to 14, and the desired HLB value may be obtained by appropriate blending. Depending upon their HLB, PGEs can act as water-in-oil (W/O) or oil-in-water (O/W) emulsifiers.

PGEs form highly stable alpha-gel in water. The α-gel phase of PGEs is surface active and is able to stabilize foams when the temperature is lower than the melting temperature of the emulsifier. The special structure also leads to better emulsification properties.

Application

An important application of PGEs is in cake batters with little or no content of fat and oil (i.e. batters for sponge cakes, Swiss rolls and similar types of cake formulations that are based on egg, sugar and flour and/or starch). PGEs enhance aeration and help stabilize foams. The use of PGEs makes it possible to produce sponge cakes by single stage mixing, and produce final products with a finer crumb structure and longer shelf life.1

PGEs can be used in margarines. The addition of PGEs improve the functional properties of the margarine (e.g. the organoleptic properties of spreads, stabilizing or aerating of food) in addition to the emulsification of the emulsion. PGEs are reported to improve the organolepic properties of a margarine or low-fat spread by reducing the graininess of the lipid phase to yield a plasticity and elasticity of the margarine corresponding to natural butter.4

Compared to alternative emulsifiers, such as monoglycerides, the polyglycerol ester is found to have an advantage in providing long-time stability of whipping properties, making the emulsifier an excellent choice for cake mixes.

PGEs can also be used as low fat shortening.1 They can also form emulsion systems with a high amount water, thus reducing the overall caloric content of a food product. As the α-tending emulsifier, PGEs also have the crumb softening and anti-staling effects and they also help improve cake volume in baked products. The reason is that emulsifiers can reduce the rate of starch retrogradation.

PGEs can be used in whippable emulsions and toppings. They can promote fat particle aggregation and water absorption, and help achieve increased viscosity and aeration, and reduced coalescence.

Different than monoglycerides (MGs), the α-gel structure formed by PGEs are thermodynamically more stable, which means the emulsion system formed by PGEs are more stable than that of MGs.1 Blends of PGEs and MGs are known to improve sponge cake aeration and stability with less mixing time and improved foam and emulsion stability.1

FDA Regulation

PGEs are permitted for direct addition to food as additives for human consumption, which is regulated by FDA in the Code of Federal Regulations 21CFR172.854.3

References

- Wang, Fan C., and Alejandro G. Marangoni. “Advances in the Application of Food Emulsifier α-gel Phases: Saturated Monoglycerides, Polyglycerol Fatty Acid Esters, and Their Derivatives.” Journal of Colloid and Interface Science 483 (2016): 394-403. doi: 10.1016/j.jcis.2016.08.012.

- Bastida-RodrÃguez, Josefa. “The Food Additive Polyglycerol Polyricinoleate (E-476): Structure, Applications, and Production Methods.” ISRN Chemical Engineering 2013 (2013): 1-21.

- “CFR – Code of Federal Regulations 21CFR172.854.” U.S. Food & Drug Administration. 1 Apr. 2016. www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=172.854. Accessed 01 Jan. 2017.

- Norn, Viggo. “8. Polyglycerol Esters.” Emulsifiers in Food Technology. Chichester, West Sussex, UK: Wiley Blackwell, 2015. 195-204.