Scaling up is the science (mostly) and art (a bit of creativity) of moving from small product batches to large-scale, high output production. As small and artisan bakeries seek to expand business opportunities, bread production scaling is one of the major challenges these operations may face. How do you replicate the boutique personal touch en masse? There are highly specialized consultants, experienced bakers and engineers that can assist with this exciting—yet sometimes nerve wracking—task. However, there are some basic considerations every baker should analyze before making the move.

Ingredients for Success in Bread Production

Any bakery executive who wishes to make significant changes to production models needs to visualize operations as a whole with a comprehensive view of all resources required for making bread (i.e., workforce, equipment, ingredients, materials handling) and how these may interact at the manufacturing level.

Things to consider when scaling up production include:

- Demand forecast, both in terms of product type and volume (short, medium and long term).

- Floor space availability.

- Equipment sizing and capacity analysis based on demand (daily and weekly).

- Production asset acquisition (bulk materials handling systems, mixer, divider, makeup or dough forming equipment, proofer, oven, cooler, packaging technology, conveyor or material transfer systems for product and dough).

- Line balancing (establishing optimum production rate based on demand, product size and equipment capacity, connecting all main stages and ancillary equipment of the process line). Usually expressed as dough pieces per minute.

- Production bottlenecks (capacity-limiting equipment).

- Line staffing (minimum personnel required for operating machinery or transferring minor and/or micro ingredients).

- The assurance (and methods to guarantee) that product quality will be maintained despite changes in processing technology.

- Personnel training.

- Product formulation adjustments (if needed to adapt to new processing conditions).

The Oven is the Key Equipment System for Successful Production Scale-Up

It is well known that ovens have the greatest financial impact when scaling up bakery operations. A bakery’s production capacity is, in most cases, a function of how many loaves of bread the oven can handle per batch / hour in order to serve customers, comply with supply agreements and keep up with extra daily demand. This is why it is critical for bakery managers to understand how ovens operate and how to optimize their function and output.

High-speed ovens allow bakers to produce more bread and to also transition from manual production to a semi-automated, smooth and continuous operation. But, don’t be fooled: It can be tricky to transition from old, batch-type ovens to tunnel or conveyorized ovens which require precise recipe settings and detailed PID control programming.

How ovens react to gaps, full product loads (i.e. dough, pan, lid), steam injection, and many other conditions should be carefully understood in order to fine-tune all heat transfer components that affect global heating capabilities of the equipment (e.g. burner(s) capacity, exhaust system, band heating/cooling cycles, heat losses through insulation and outer covers, etc.). This is critical since heat governs how fast dough transforms into crumb and how well the crust develops and thickens to provide loaf integrity, which is crucial to preventing collapse upon cooling and slicing.

Profiling for Fine-tuning New Ovens

One thing that often happens when using a new and more powerful oven is that the baked product may not result in the same crust color as was produced with previous systems. Crust color may not be as even, crumb moisture content is different, and overall product characteristics have changed. Such situations call for careful evaluation of bake times and alternative bake temperatures. Obtaining more information and data from the baking process should be the first step in understanding these changes and implementing corrective action, if required. This can be achieved with the help of thermal profiling processes and close observation of finished product characteristics.

A bakery which has access to a thermal profiler prior to decommissioning an old oven can more quickly achieve process compatibility with the new oven. In this case, comparative product data exists and can be transferred to the new oven’s control parameters for consistent (or improved) quality between existing and new ovens.

Thermal profiling can be a valuable tool which eases the scale-up process and helps bakers achieve a smooth transition to higher capacity, more complex and/or highly automated equipment; especially when it comes to ovens, proofers and cooling equipment.

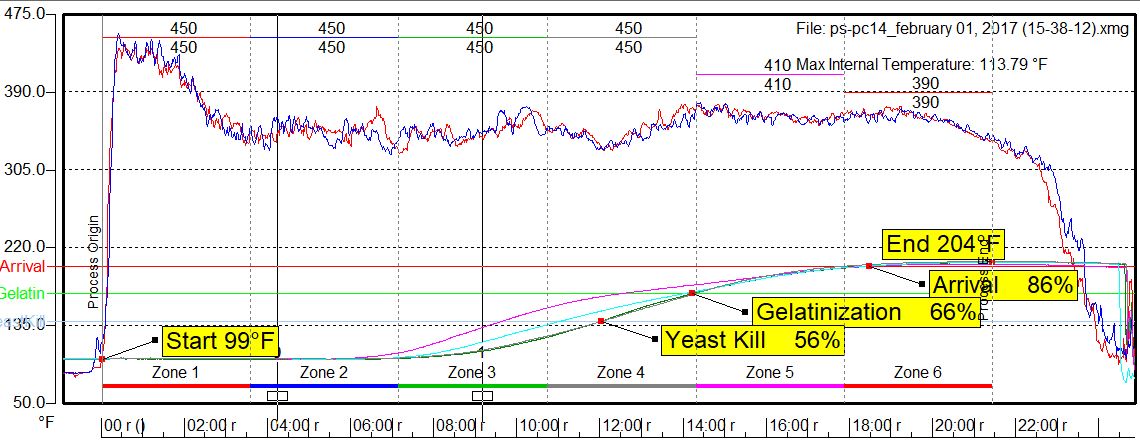

Profiling helps bakers visualize the heating rate of the product, expressed as dough temperature increase, while it transforms into bread inside the oven chamber. Thermal profiling also aids in identifying improvement opportunities in heat distribution and for verification of overall equipment component function (e.g. exhaust system, burner operation, electrical resistances, radiators, convection fans, etc.). In fact, thorough information about oven operation can be obtained from simple temperature readings which, once plotted, create the S-curve and air temperature fluctuating around the set point. (Figure 1)

Figure 1: S Curve Profile Data showing key milestones in the baking process.

Tipping the Scale (Up)

Making big changes to any successful baking operation — no matter the size — can be overwhelming. The key, of course, is ensuring that the business can repeatedly produce baked goods with the same taste, color and smell that have helped the products and brand develop loyal customers. Using tools like thermal profiling technology are central to successfully scaling up. Measuring results, verifying system performance and continually monitoring the process will yield consistent results day in and day out. Leveraging the power of data and data analysis through the use of thermal profiling can help tip the scale toward more profitability.