One-third of food produced for human consumption is lost or wasted globally.1 For the commercial baking industry, food waste can occur at any stage in the process. Food is lost or wasted throughout the supply chain, from initial agricultural production down to final household consumption.1

What are the causes of food waste?

The causes of food waste can be broken into three segments:

Farm or Production Level:2

- Consumption or damage by insects, rodents, birds or microbes

- Spillage and damage, such as equipment malfunction or inefficiencies during harvesting, drying, milling transporting or processing

- Industry or government food safety regulations or standards that cause some products to be rejected for human consumption

Retail Level:2

- Spillages, abrasion, bruising, excessive or insufficient heat, inadequate storage, technical malfunction

- Out-grading of blemished, misshapen, or wrong-sized food in an attempt to meet consumer demand

Consumer Level:2

- Sprouting of grains and tubers, mold in baked goods

- Consumer confusion over “use-by” and “best-before” dates, so that food is discarded in packaging

The total value of food loss at the retail and consumer levels in the United States in 2008 was estimated at $165.6billion.2 Grain products accounted for $10 million or about 30% of food loss, compared with poultry at 41%.2 This could be due to the fact that grain is often diverted to animal feed.

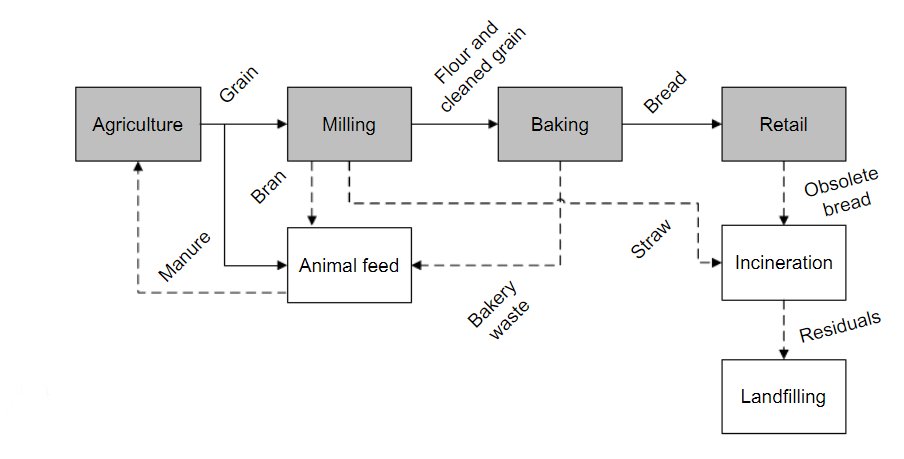

The supply chain for baked goods can be seen in Figure 1.

The Solution?

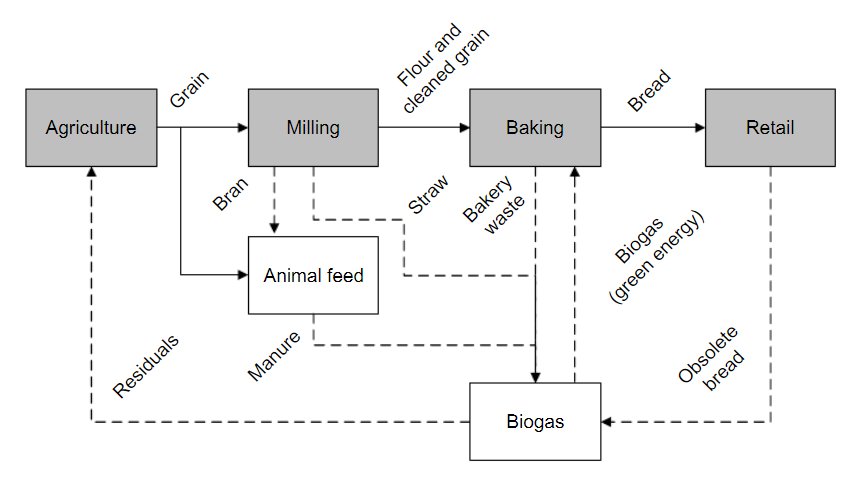

A green supply chain or closed-loop supply chain suggests a system in which the whole chain must work together to eliminate food waste. A case study researched a retailer, and industrial bakery, a mill and a farmer.3 The study suggests using food waste from the baking supply chain to create biogas to contribute to a green supply chain.3

- Reduce changeovers on the line

- Provide proper sanitation standard operating procedures (SOP) to enable preventative maintenance (PM)

- Do PM on the mixers, dividers, proof box and ovens once a week. The shutdown of this equipment results in high levels of food waste.

- Provide opportunities for the R&D and production departments to improve efficiencies.

- Redirect food waste to those in need.1

- Source sustainable ingredients and implement a food loss prevention program.

- Convert food waste to biofuel or animal feed.4

- Develop packaging innovations to extend shelf life and protect products during transport.5

Converting food waste into fuel is one potential solution. Food waste is nutrient-rich, and fermentation processes make it a possible resource for biofuel. The final products of fermentation are biogas, hydrogen, ethanol, and biodiesel.4 Many companies have already transitioned to packaging solutions that protect consumer packaged goods during transport and extend shelf life. Food waste will continue to be an issue for the commercial baking industry. Bakers face unique challenges when analyzing the supply chain to reduce food waste.

References

- “Food Loss and Food Waste.” Food and Agriculture Organization of the United Nations, www.fao.org/food-loss-and-food-waste/en/.

- Buzby, J.C., and J. Hyman. “Total and Per Capita Value of Food Loss in the United States.” Food Policy, vol. 37, no. 5, 2012, pp. 561–570.

- Jensen, K.J., K.B. Munksgaard, and J. Stentoft Arlbjørn. “Chasing Value Offerings through Green Supply Chain Innovation.” European Business Review, vol. 25, no.2, 2013, 124–146.

- U. Kiran, A.P. Esra, W.J. Ng Trzcinski, et al. “Bioconversion of Food Waste to Energy: A Review.” Fuel, vol. 134, 2014, pp. 389–399.

- Verghese, K., H.S. Lewis, and H. Williams. “Packaging’s Role in Minimizing Food Loss and Waste Across the Supply Chain.” Packaging Technology and Science, vol. 28, no. 7, 2015, 603–620.