Brought to you by ECD

Thermal profiling is an essential procedure for any top-quality bakery that optimizes baking processes. Ensuring that ovens are performing properly and that dough is reaching the desired temperatures, the thermal profiler is a must-have tool for modern bakeries. But, with the temperatures these devices will see inside the oven, protecting them with a thermal barrier is a necessity for repeatable, long-lifetime performance.

Using BakeWATCH® M.O.L.E.® as an example, the following will offer a guide to selecting a thermal barrier to a 3-, 6- or 20-input M.O.L.E..

Importantly, the thermal barrier is responsible for providing longevity to the electronic data recorder for many years of productive bakery process optimization for applications such as:

- Proofer validation profiling

- Oven balancing and line comparisons for yield improvement

- Baked goods optimization profiling and S-Curve management

- Free-from reformulation NPIs

- Post-bake HACCP D-Reduction Kill Step profiling

- Cooling line profiling

- Blast freezer profiling

There are four main constituents of a thermal profiling kit for bakeries:

- The electronic data recorder (M.O.L.E.® thermal profiler), which has a sufficient number of sensor inputs to measure and record data from multiple good and ambient dough locations simultaneously during production.

- A thermal barrier, properly sized to fit through the ovens and all systems, while providing sufficient thermal protection for particular product variety time and temperature bake cycles (zone settings and conveyor speed/time).

- Thermocouple sensors of the appropriate length, wire gauge, insulation performance, connector type and calibration type.

- Software furnished by the same company that designs and builds the thermal profiler from which to extract actionable data to maximize yield and profitability.

Due diligence in selecting a thermal barrier can begin by visiting a supplier’s website, where one will find detailed datasheets (“Armor Charts”) that show time/temperature graphs for multiple thermal barrier models including selection tables, dimensions and weights.

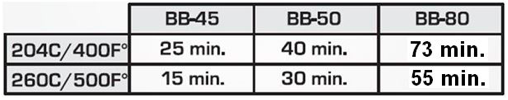

For instance, a typical breads and buns bakery can confidently specify the mid-range BB-50 thermal barrier – the most frequently purchased model. For a bakery specializing in denser multigrain varieties with bake times exceeding 30 minutes, it is prudent to select the BB-80 model, which adds active phase-change heat sink technology to the insulation stack in base and lid. The BB-80 is especially recommended for gluten-free specialists and cheesecake bakeries.

Optimize Baking Processes: Bread

Flatbreads such as pita and pizza crusts, as well as crispy snack goods like crackers and biscuits, require unique thermal profiling solutions for quality and food safety needs. The challenge is high temperature settings through low height 2” maximum clearance high-speed tunnel ovens. These applications are routinely solved with the BB-45 or even a 1”/254 mm Uni-Barrier to protect against temperatures up to 320°C/608°F for 4 to 12-minute bake times.

Therefore, basing a thermal barrier choice upon the time and temperature of the varieties baked while accommodating internal clearance restrictions, one can expect to reap the following benefits of thermal profiler protection:

- Diminished wait time between profile runs (to allow thermal profiler cooling)

- Especially important during multiple Kill Step profile runs for FSMA compliance reporting

- Maintain thermal profiler operating range rating for accuracy and operational consistency

- Bakeries can have the assurance of ovens and baked goods profiling benefits for many years beyond the initial ROI of their thermal profiling tools purchase by using the appropriate thermal barrier

With a properly-sized thermal barrier, profiler deployments and retrievals become routine practice and the profiler is protected to maximize investment and boost profitability. Learn More