Why do consumers ask for bakery products that are free from egg?

Health- and sustainability-conscious consumers are driving the “free-from” trend by asking for egg-free alternatives. Numerous recent public health concerns, such as avian influenza and fipronil contamination, have also increased the importance of egg replacement. Moreover, egg is a costly ingredient with considerable supply and price fluctuations. Being able to partially substitute eggs helps to buffer raw material shortages while guaranteeing a constant quality of baked goods.

What is the challenge?

Replacing eggs can be very challenging, as they are an essential, multi-functional component in many fine bakery products. Egg has a major impact on fine baked goods, from the processability of the batter to the determination of quality parameters such as volume, texture, taste and shelf-life.

Is there a solution for 100% egg replacement without quality deficits?

Yes, there is an innovative solution for replacing up to 100% egg in cake and other fine bakery products: α-cyclodextrin. This naturally occurring oligosaccharide is made from starch and can be obtained from WACKER under the trade CAVAMAX® W6. In combination with water and protein (either plant or dairy based), α-cyclodextrin represents a solution for up to 100% egg replacement in ready-to-use powder mixes or final baked goods that still fulfill the quality and sensory expectations of consumers.

Advantages of using α-cyclodextrin:

- α-Cyclodextrin allows manufacturers to replace egg without compromising on product quality and can simply be added to powder premixes for easy handling.

- In comparison to egg, which can be difficult to handle, α-cyclodextrin allows producers to employ a leaner HACCP management.

- Because it has no major influence on batter pH or viscosity, α-cyclodextrin can be used on existing equipment and production lines.

- Replacing egg by α-cyclodextrin can reduce costs by up to 40% and additionally provides a buffer for seasonal egg-price deviations.

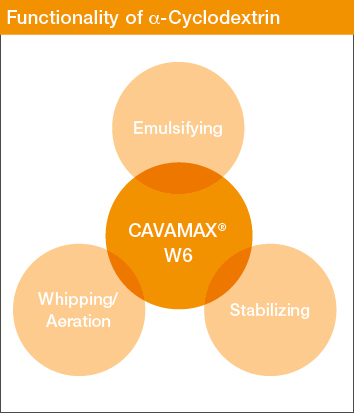

α-Cyclodextrin improves batter aeration and the stability of fat droplets and gas cells. The synergy of α-cyclodextrin with proteins stabilizes the texture and retains the moistness of the final baked good. The graphic on the left summarizes the functionality of α-cyclodextrin (CAVAMAX® W6) in bakery products.

How to replace eggs

The combination of α-cyclodextrin, protein (dairy or plant-based) and water can be used to replace some or all of the egg in a formulation. This works for liquid egg as well as for powdered egg. In which products can α-cyclodextrin replace egg? The proven solution has already been tested in:

- Pound cake

- Sponge cake

- Layer cake

- Muffins

- Yeast leavened applications

- Further applications are possible

Watch the video to see for yourself:

Analysis of texture and taste verifies excellent quality with α-cyclodextrin

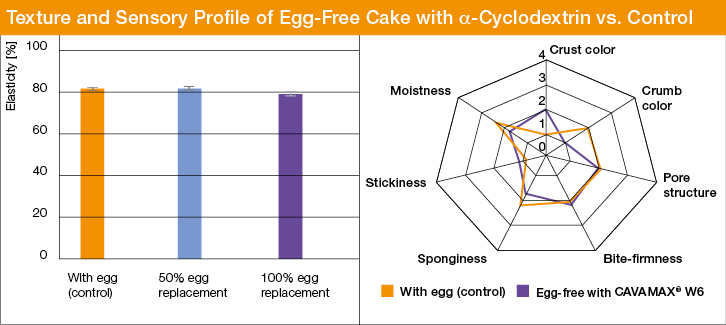

Eliminating egg in a cake typically results in reduced volume and elasticity. α-Cyclodextrin compensates for the loss in elasticity, as shown in the graph below. The sensory parameters of cake made with α-cyclodextrin are likewise very similar to those of the egg-containing control. Variations in color can easily be adjusted by adding beta-carotene.

Left: Elasticity of pound cake crumb measured via texture profile analysis. Cakes with partial (50%) and 100% egg replacement contain α-cyclodextrin (CAVAMAX® W6). Protein and water content have been adjusted accordingly.

Right: Sensory analysis of pound cake with egg and 100% egg-free (egg replaced with 1% CAVAMAX® W6 α-cyclodextrin); adjusted protein/water content.

CAVAMAX® is a trademark of Wacker Chemie AG.