Flour: Lively and Complex

Cookies, crackers, noodles, tortillas, cakes, buns, sandwich breads, flat bread, wafers, baguettes, and so on…. No matter the finished product, all bakery products come in an infinite variety of shapes, sizes, composition, texture, tenderness, colors, and tastes.

Because their recipes are relatively simple, their quality depends greatly on the properties of the flour, and the dough—water absorption of flour, quantity and quality of proteins, characteristics of the dough (consistency, extensibility, elasticity, stickiness, viscosity, etc.), amylase enzyme activity, starch properties (damage, retrogradation), development and holding of dough during fermentation—all impacting the manufacturing processes and the quality of the final products (volume, color, cracks, blisters and more).

Identifying the key elements that affect the final quality of the product is essential in order to implement effective quality control (QC), keeping in mind that the mechanisms involved differ for each production line.

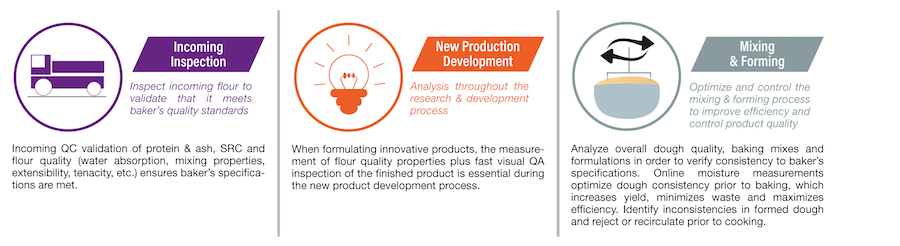

Chopin Technologies provides solutions for measuring the primary criteria affecting final product quality, at each steps of the baking process:

Our Company

Analyzing cultivars and grain & flour quality is essential for breeding, proper harvest timing, outbound & inbound QC inspection, proper grain allocation, and development of innovative formulations.

CHOPIN Technologies, a KPM Analytics brand, provides a full suite of premium instrumentation ideal for the quality and control of grain and flour used across the grain, milling and baking processes.

The other brands within KPM Analytics (EyePro, Sightline, Unity Scientific, Process Sensors, and Sensortech) also offer a wide range of solutions to bakers for greater control during process:

- At “proofer, oven and cooler” step— Increase yield and reduce waste with QC verification before and after the oven.

- For final product verification— Compositional analysis and rejection of sub-grade product to ensure only the best quality product.

- For packaging— Fast and accurate count, sort, seal, label, and barcode analysis for food safety and lot tracking throughout the packaging process.

Contact us