Oven Humidity

What is Oven Humidity?

Oven humidity is an important variable in baking operations. Along with time, temperature and air flow (in convection ovens), it is used to better control the baking step.

- The temperature in an oven is higher than the boiling point of water (212°F or 100°C at sea level) and far beyond the temperature range where moist air can be modeled as a perfect gas.

- So, humidity inside the baking chamber cannot be measured as relative humidity.

- Instead, the absolute humidity concept or humidity mass ratio is used.1,2

How does oven humidity work?

Baking chamber moisture, a function of drying and a product of combustion, is defined in terms of mass of moisture relative to the dry air present (Lb water/Lb dry air). Or, as dew point: the temperature at which moisture in the air condenses on a surface.3

Humidity in an oven influences the 2 transport processes that take place during baking:

- Heat transfer: the energy, in the form of heat, is transferred into the product and causes dough/batter temperature to rise. This is reflected in physicochemical changes such as water/ethanol evaporation, expansion of gases, starch gelatinization, protein denaturation and Maillard browning.

- Mass transfer or moisture migration: due to the drying nature of the baking step, water migrates from the product interior to the dough surface. Evaporation in the baking chamber increases the hot air humidity. The amount of water vapor inside the oven also affects the rate of heat input into the dough or batter.

Baking parameters influenced by oven humidity

- Crust color: High humidity lightens the crust color of baked goods. This is because excess humidity blocks direct transfer of heat to the product. In addition, the condensates formed on the dough surface act as a natural insulation to heat transfer. Under this scenario, crust temperature during baking is lower than the target resulting in light-colored finished product.

- Dough expansion and product volume: High humidity increases the volume of baked products. A baking chamber rich in moisture decreases the driving force for water migration. So, less water is lost from the product to hot air, causing dough/batter to remain moist to expand/stretch further before the crust sets.

- Moisture content: High humidity raises the final moisture content of the baked product which influences product shelf-life and sliceability.

- Crust character: Some artisan and hearth breads require steaming to generate surface condensation and produce a glossy and shiny crust. Higher humidity will result in a glossier and thicker product crust.

Factors that influence oven humidity

- Oven load: Humidity inside the oven increases as more products enter the baking chamber. At the same time, heavier loads require more heat to evaporate the water. This results in a slight temperature drop in concert with the humidity increase.

- Temperature: Absolute humidity is lower at low oven temperatures because water evaporates more rapidly at higher temperatures.

- Oven steaming: During the first few minutes of baking, large amounts of low-pressure steam are injected into the baking chamber. Saturation level of steam and the amount of steam used in the oven both affect on the humidity levels.

How does steam injection effect bread baking?

Determining oven humidity

A humidity sensor can be used to measure oven humidity at product level and with the oven under full product load. It is used to study:

- The relationship between oven moisture and finished product moisture

- Optimize extraction/purge mechanisms to avoid excessive loss/build up of moisture and heat from the baking chamber that could compromise product quality

- Optimize product crust appearance

How to control oven humidity

- Purge systems: Oven humidity and distribution of heat are usually controlled by fixed-speed extraction fans and/or dampers. They can be adjusted manually or via motorized valve controlled by PLC. In modern ovens, it is usually controlled by variable-speed extraction fans.

- Air refreshments: In some applications and for safety reasons moist hot air can be replaced by fresh air during the baking cycle leading to improvements in product characteristics.

- Steam injection: Monitor and adjust the saturation level, pressure and amount of steam being injected into ovens that bake hearth and artisan breads.

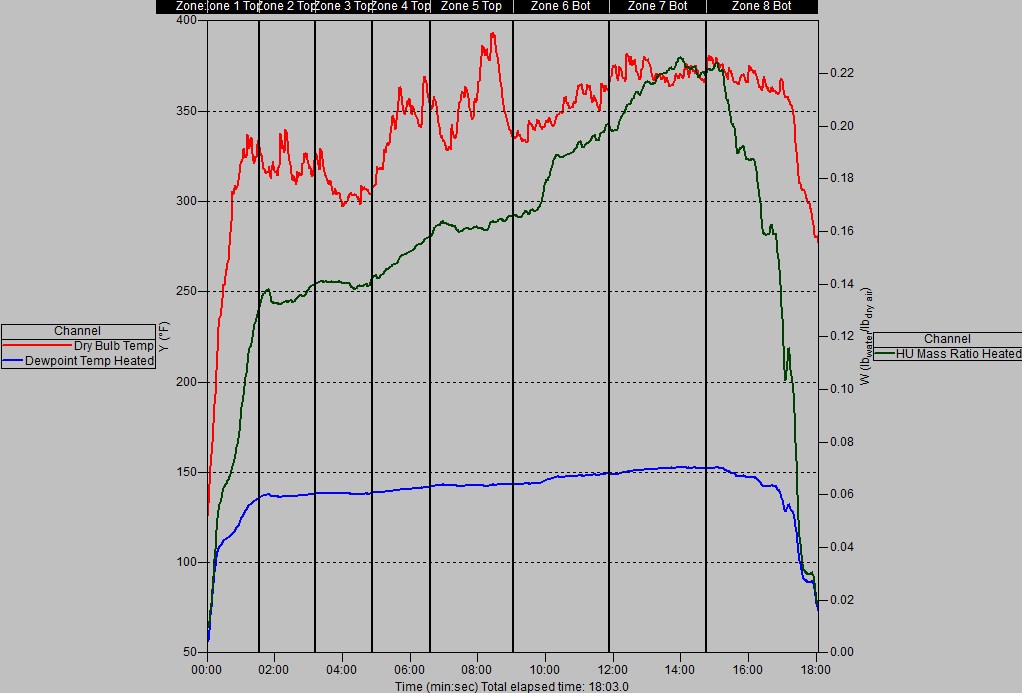

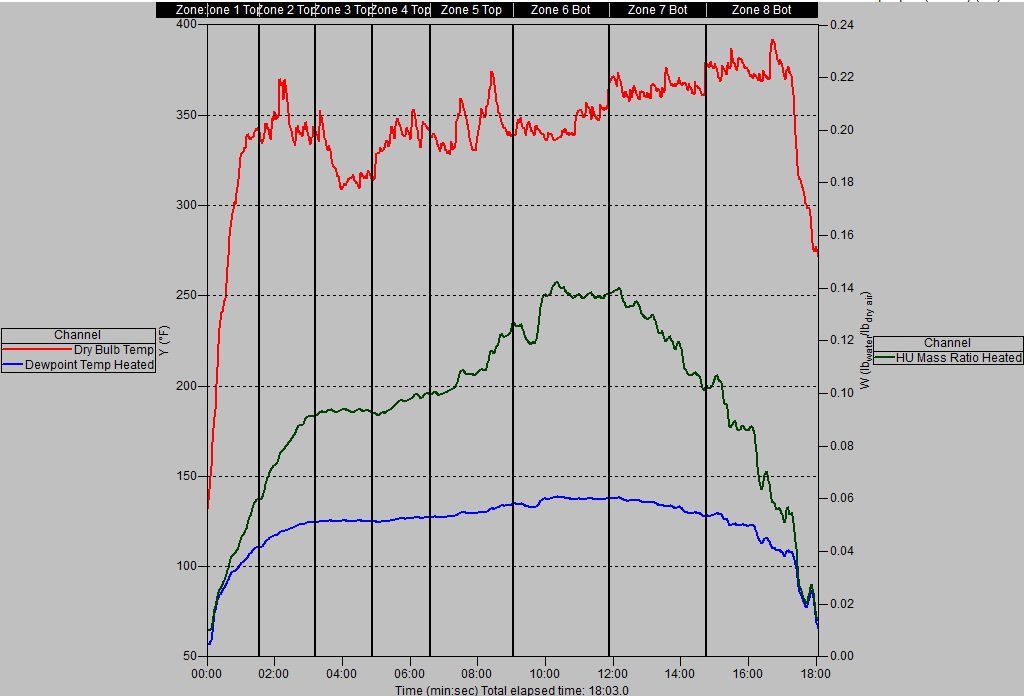

The following graphs show the difference in humidity in the oven with the damper open or closed:

Damper open:

Damper closed:

References

- Gatley, D.P. “Relative Humidity.” Understanding Psychrometrics, 3rd edition, American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., 2013, pp. 127–132.

- Singh, R.P., and Heldman, D.R. “Psychrometrics.” Introduction to Food Engineering, 5th edition, Academic Press, Elsevier Ltd., 2014, pp. 593–611.

- Manley, D. “Biscuit Baking.” Manley’s Technology of Biscuits, Crackers and Cookies, 4th edition, Woodhead Publishing Limited, 2011, pp. 477–486.