Solvent Retention Capacity

What is Solvent Retention Capacity?

Solvent retention capacity (SRC) is a physical test performed on hard and soft wheat flours to determine their end use, baking quality and hydration performance during mixing.1

The SRC test examines the water absorption and retention profile of gluten proteins, damaged starch and pentosans by using four different types of solvents: water, sucrose, sodium carbonate and lactic acid. It offers bakery and mill scientists and laboratory technicians the possibility to:

- Describe the flour’s ability to absorb water during the mixing process and its ability to release that water during the baking process

- Analyze the level of starch damage in flours

- Establish a flour quality profile for predicting functionality and specification conformance

Origin

The SRC profiling test was originally developed by doctors Harry Levine and Louise Slade while working at the Nabisco Company in the late 1980s for the quality assessment of cookie and cracker flours. Although SRC testing was originally created and developed for evaluating soft wheat flour functionality, it is now being increasingly applied to evaluate hard wheat products as well.2

SRC technology is a unique diagnosis tool for predicting flour functionality, and its applications in wheat breeding, milling, and baking are increasing as a result of its extraordinary flexibility and broad scope.

How does an SRC test work?

SRC provides an evaluation of the solvent compatibility or water affinity of the three functional polymeric components of flour (gluten, damaged starch, and pentosans). This enables prediction and better understanding of the functional contribution of each of these flour components to the overall flour functionality and resulting quality of finished product.1

Such measurement is based on proteins and polysaccharides capacity to bind water, imbibe and retain it within a matrix or gel and undergo polymeric glass–rubber transition (hydration process).3

The following table present the water holding capacity of the main functional components of wheat flour:1,4

| Component | Water Holding Capacity (g H2O / g dry substance) |

| Gluten proteins | 2–3 |

| Pentosans* | 10–15 |

| Starch (native/raw) | 0.3–0.45 |

| Damaged starch** | 1.5–10 |

| Gelatinized (pasted) starch | > 10*** |

*Varies according to genetic and agronomic factors

** Varies according to milling conditions

*** Only limited by granule bursting or maximum swelling

The SRC test consists of the following steps:5

- Preparation of solvent solutions (weighing of reagents, solutes and deionized water)

- Weighing of flour

- Addition of flour sample into test-tube containing solvent

- Mixing/shaking of suspension

- Holding or solvation time

- Centrifugation of suspension

- Decanting and draining of supernatant

- Weighing of pellet (humid gel residue)

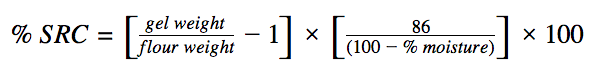

- Determination of SRC for each solvent according to following equation:6

Generally, lactic acid SRC is associated with glutenin characteristics, sodium carbonate SRC with levels of damaged starch, and sucrose SRC with pentosan characteristics. Water SRC is influenced by all of those flour constituents.2

SRC values highly correlate with rheological or physical dough tests such as extensograph, alveograph, farinograph. Generally, flours from hard wheats exhibit good breadmaking characteristics; their doughs have higher water absorption require more time to mix to reach full development, have more baking strength, and higher SRC values.

On the other hand, soft flours for cookies and crackers production generally require low water absorption , minimal gluten strength, and low damaged starch to obtain excellent spread. These characteristics are also vital to minimize energy consumption for water removal during baking.5

Components of flour directly involved in water hydration and main applications:

| Wheat Type | Components of Patent or White Flour7 (%) | SRC Values | Application or End Use |

| Soft Wheat |

|

Expected to be lower |

|

| Hard Wheat |

|

Expected to be higher |

|

*Varies according to endosperm extraction from whole wheat

** Percentage of the total starch in the flour

References

- Carlos Guzmán, et al. “A new standard water absorption criteria based on solvent retention capacity (SRC) to determine dough mixing properties, viscoelasticity, and bread-making quality.” Journal of Cereal Science, 66 (2015): 59–65.

- Lynn C. Haynes, Arthur D. Bettge, and Louise Slade. “Soft Wheat and Flour Products Methods Review: Solvent Retention Capacity Equation Correction.” AACC International Report, 174 / July-August 2009, Vol. 54, No. 4.

- Damodaran, S. “Amino Acids, Peptides, and Proteins” Fennema’s Food Chemistry, 5th edition, CRC Press (Taylor & Francis Group, LLC), 2017, pp. 284–292.

- Finnie, S., and Atwell, W.A. “Composition of Commercial Flour” Wheat Flour, 2nd edition, AACC International, Inc., 2016, pp. 31–41.

- Meera Kweon, Louise Slade, and Harry Levine. “Principles and Value in Predicting Flour Functionality in Different Wheat-Based Food Processes and in Wheat Breeding—A Review.” Journal of Cereal Chemistry. 88 (6): 537–552.

- AACC International. Approved Methods of Analysis, 11th Ed. Method 56-11.01. Solvent Retention Capacity Profile. Approved November 3, 1999. AACC International, St. Paul, MN, U.S.A.

- Carson, G.R., and Edwards, N.M. “Criteria of Wheat and Flour quality” Wheat Chemistry and Technology, 4th edition, AACC International, Inc., 2009, pp. 97–100.