Frying

What is Frying?

Frying is a thermal food process that is widely used in the production of snacks and bakery products. Similar to baking and extrusion, it is used to impart unique textures, flavors and aromas to a variety of foods.

Products traditionally made by frying include:

- French fries

- Tortilla chips

- Donuts

- Potato chips

- Breaded chicken (broaster)

Origin

Frying is one of the oldest known food preparation and cooking techniques. However, it’s hard to trace the exact date of its introduction and who first used it. Some sources claim that it was invented by the ancient Chinese trying to cook meat in 3000 BCE, while other theories suggest that it was first used by the Hebrews for making flat bread.1

How does it work?

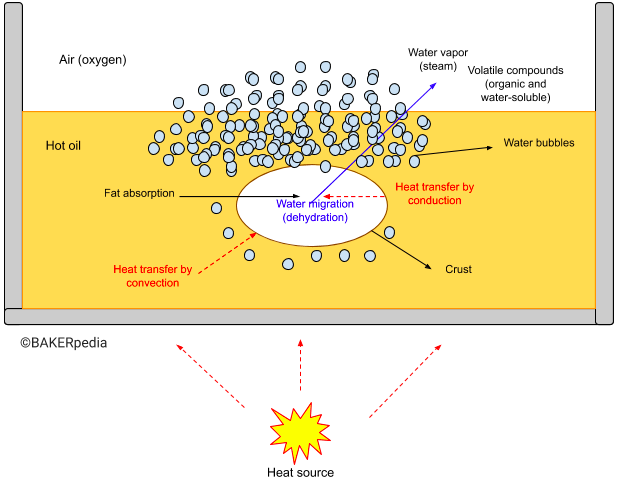

The frying process involves heat and mass transfer (moisture and fat migration) phenomena. It uses hot oil or frying fats at 302–392°F (150–200°C) as a heat transfer medium to cook products. These products can be frozen or just at room temperature. During the process, heat and mass transfer take place simultaneously.2,3

Heat is transferred to the surface of the product by convection, and from the surface to the product’s core, by conduction. Just like baking, it is carried out under atmospheric conditions where the fried product reaches internal temperatures close to 100°C. At that point, the moisture turns into vapor.

Biochemical transformations start happening with the increase in product temperature. Other physicochemical processes such as starch gelatinization, protein denaturation, non-enzymatic browning also take place. Simultaneously, water in the food being fried migrates from the center to the outside, thus replacing the moisture that has just escaped in the form of water vapor to the surroundings while fat migrates to the inside of the fried food or dough piece.

Application

There are two types of methods used:2,3

- Surface frying: About half of the product is covered with oil.

- This frying process is used in the production of donuts (batter-or dough-based). Cake and yeast donuts become porous and less dense during frying due to leavening reactions, expansion of gases trapped and vapor release.

- As a consequence, these products have a strong tendency to float to the top leaving one side exposed to the air (unfried). For even frying, donuts are usually turned over half-way during the cycle. A characteristic white ring appears at the donuts mid-height.

- Deep-fat frying: Product is totally covered with oil.

- This method is traditionally used in French fries production. When used in processing donuts, the mid-height white ring does not form.

Equipment

Modern frying equipment is constructed from high-grade stainless steel without any copper or brass in any valve fitting or heating element to avoid fat oxidation catalysis. This equipment can be divided into two categories: batch and continuous.

Batch frying equipment

The most common batch-mode fryer is a kettle or jacketed vessel that is used in small plants and catering restaurants.

Continuous frying equipment

Used in high-speed facilities that need to process larger amounts of product. They are mostly automated units, often operated under atmospheric conditions. New designs are available which can be operated under lower (vacuum) or higher pressures. Continuous equipment consist of a frying vessel where oil is maintained at the desired temperature via a thermostat-regulated closed loop, a conveyor (flights) that carries the product through the unit and an extraction system that eliminates the fumes (primarily made up of moisture and a fine mist of fat).

Heating fat/oil mechanism2,3

Direct:

- Uses electrical resistances (heaters) or a battery of gas burners located at the bottom of the bath

Indirect:

- Uses gas-fired flames or turbo-jet infrared burners placed underneath the frying vessel

- Pumps a heated thermal fluid into pipes immersed in the oil bath

- Continuous removal of the frying fat at a discharge end of the frying tank, pumping the fat through a filter and then through a remote heat exchanger before fat is returned to the frying vessel.

Frying Process variables:

- Time

- Temperature of fat

- Fat/oil chemical composition (indirect indicator of stability)

Oil absorption in selected fried products

| Food product | Gram fat absorbed / 100 g product |

| Frozen French fries | 5 |

| Fresh French fries | 10 |

| Breaded food (fish/chicken) | 15–20 |

| Potato chips | 35–40 |

| Cake donuts | 15–20 |

| Yeast donuts | 10–15 |

References

- Zeb, A. “Food Frying.” Food Frying. Chemistry, Biochemistry, and Safety, John Wiley & Sons Ltd, 2019, pp. 3–21.

- Bouchon, P. “Food Deep-Fat Frying.” Food Processing Handbook, 2nd edition, Wiley-VCH Verlag & Co. KGaA, 2012, pp. 455–483.

- Erdogdu, F., and Palazoglu, T.K. “Food Frying Process Design.” Handbook of Food Process Design, 2 Volume-Set, Blackwell Publishing Ltd., 2012, pp. 789–806.