Rice Flour

What is rice flour?

Rice flour is finely milled rice used principally in gluten-free baking or as a dusting powder in commercial scale baking operations. Starch is the most important fraction of this flour and is detrimental to its functionality in food systems such as baking, noodles, gravies, crackers and many others.

Rice flour, either brown or refined, is used in gluten-free baking as a key ingredient for polymeric network formation and as dusting powder for high hydration doughs to prevent dough stickup.

- It has a neutral flavor

- Its color ranges from white to brown (depending on bran content)

- It’s digested easily

- It is considered hypoallergenic

Origin

Rice flour is produced from the Oryza sativa plant, an important cereal that forms the staple article of food of many Asian populations, mainly in China, India, Indonesia, and more recently in North America and parts of Africa and South America.

Rice can be classified based on:

- Grain length (long, 6.6-7.5 mm; medium, 5.5-6.6 mm and short (less than 5.5 mm)

- Color (brown vs white)

- Amylose content (low such as way and glutinous rice or high amylose)

This flour has a pleasant mellow flavor, but contains no gluten-forming proteins so it cannot form a viscoelastic network and gas retention.

Function

Rice flour is used as an alternative to wheat flour in gluten-free baked goods. Bread produced with this ingredient has lower loaf volume, harder texture, and shorter shelf life.

When used in gluten-free bread, it is important to use it in combination with other flours, starches, gums, and enzymes to help mimic the gluten matrix and improve water absorption.

Composition of rice flour starch compared to wheat flour starch

| Flour Type | Amylose (% of starch) | Amylopectin (% of starch) | Gelatinization Range (°C / °F) | Granule Diameter (microns) | Granule Diameter (microns) |

| Wheat | 25 | 75 | 58-64 | 1-45 | Round, lenticular |

| Rice (long grain, white) | 23-26 | 74-77 | 71-74 | 3-8 | Compound

Polygonal granule |

| Rice (short grain, white) | 18-20 | 80-82 | 65-67 | 3-8 | Compound

Polygonal granule |

| Glutinous rice | 1-2-3 | 97-98.8 | 58-67 | 1-7 | Irregular

Polyhedral granule |

Commercial production

White rice production involves dehulling and tempering prior to milling to remove its bran. Enriching is done for table rice, but not for rice flour production unless required by the customer.

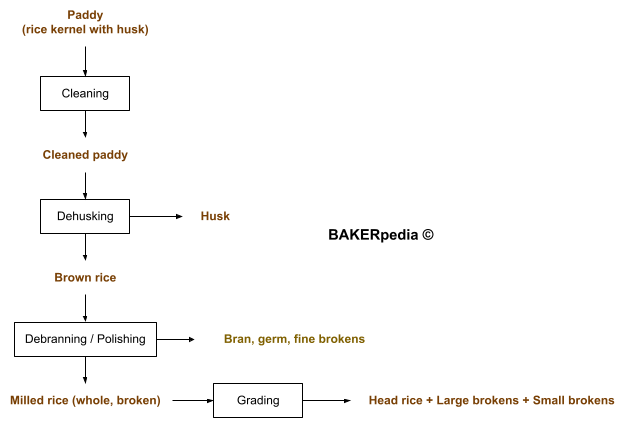

There are several milling options available, yielding different particle sizes, textures, and starch content. While ash content is detrimental in wheat flour dry milling, the lipid content is monitored for evaluating the degree of rice flour milling. Here is a process flow diagram for dry rice milling:

Different grinding methods can be used:5

- Wet grinding is the most traditional – and the most expensive – process for obtaining this flour. Wet grinding results in significantly smaller average particle size and a lower percentage of starch damaged starch than alternative grinding methods.

- Semi-dry grinding is simpler than the wet grinding method. Rice kernels are soaked and dried before they are grinded into flour. The method is expensive and time-consuming.

- Dry grinding is done without any prior soaking of the rice kernels. The kernels are ground using varying tools (e.g., hammer mill, roller mill, impact mill, pin mill, disk mill) until the particle size of the rice flour is consistent.

- Freeze grinding is a newer method that uses less energy and produces less waste from processing. Rice kernels are frozen using liquid nitrogen and then dry-ground into flour. Freeze-grinding temperatures have been shown to damage starch content in the rice flour.

Nutrition

Rice flour is high in fiber, gluten-free, and low in saturated fat, cholesterol, and sodium. It has lower nutritional value than whole-grain rice or brown rice flour, but is a significant source of manganese. Unlike wheat, oil and enzymes are distributed throughout rice’s bran, not germ.

Composition of rice flour (compared with wheat flour):

| Flour Type | Moisture (%) | Ash (%) | Fat (%) | Protein (%) | Starch (%) | Total Dietary Fiber (%) |

| Refined hard wheat | 11.9 | 0.5 | 1.0 | 11.0 | 73.3 | 2.7 |

| Brown rice | 12.0 | 1.5 | 2.8 | 7.2 | 71.0 | 4.6 |

| White rice | 11.9 | 0.6 | 1.4 | 6.0 | 77.6 | 2.4 |

Application

Rice flour is used in food for gluten-intolerant consumers. Its use in bread-making is still limited because rice proteins are unable to retain the gas produced during the fermentation process. This flour adds creaminess and crunchiness to baked goods.

Depending on its amylose content, it can be used in various baking applications. Waxy (low amylose) rice flour can be used in cakes and puddings while high amylose flour is preferred for expanded snacks and noodles. Here are some methods to enhance the quality of gluten-free products made with this flour:

- Add transglutaminase: Rice proteins are polymerized through the transglutaminase reaction, providing a protein network necessary for holding the gas produced in fermentation. With the addition of 1% transglutaminase (based on total formula weight) in the presence of 2% hydroxypropyl methylcellulose (HPMC), rice bread’s specific volume increases and its crumb becomes softer.2,3

- Add hydrocolloids: HPMC has been found to be the most suitable hydrocolloid, and yields rice bread with a specific volume comparable to that of wheat bread. HPMC can provide rice flour dough with film-forming and CO2-entrapping properties. Other hydrocolloids like CMC and xanthan gum can’t replace HPMC because they cannot deliver similar gas-retaining and film-forming properties. HPMC has been used at levels of 3.5–5.3%. Its usage level can be lowered by adding glucose oxidase.3

References

- Wei, X., and Huang, X. “Origin, Taxonomy, and Phylogenetics of Rice.” Rice: Chemistry and Technology, 4th edition, Published by Elsevier Inc. in cooperation with AACC International, 2019, pp. 1–2.

- Yano, H. Recent practical researches in the development of gluten-free breads. npj Sci Food 3, 7 (2019). https://doi.org/10.1038/s41538-019-0040-1

- Casper, J.L., and Atwell, W.A. “Gluten-Free Ingredients.” Gluten-Free Baked Products, AACC International, Inc., 2014, pp. 23–47.

- Gujral, H.S., and M.R. Cristina. “Improvement of the Breadmaking Quality of Rice Flour by Glucose Oxidase.” Food Research International, vol. 37, no. 1, 2004, pp. 75–81.

- Zhou, W., and Y. Huri. “5 Rice.” Bakery Products Science and Technology, 2nd ed., Wiley Blackwell, 2014, pp. 103–116.