How do a thermal profiler and texture analyzer work in a quality program? Here is a case study to show how you can make these tools work for you. The BAKERpedia team worked with the Wheat Marketing Center to research the production of crackers and their texture. Cracker production is unlike many other baked goods. They have low water absorption (usually less than 30%), different leavening systems and a very slack dough that can tolerate high stress reduction rollers.

While the world outside of the U.S. calls these sweet baked goods biscuits, Americans call them crackers. Crackers are thin, crispy baked products that can either be sweet or savory. We’ve used a Marie Biscuit (a very popular cracker in the British colonies) formula, which tastes very similar to animal crackers.

Cracker Formula:

| Ingredients | Baker’s % |

| Cracker flour | 100 |

| Shortening | 17 |

| Sugar | 20 |

| Lecithin | 0.5 |

| Malt extract | 0.2 |

| Honey | 5 |

| Nonfat dry milk powder | 2.5 |

| Salt | 0.8 |

| Vanilla extract (liquid) | 0.5 |

| Sodium bicarbonate | 0.6 |

| Sodium sulfite | 0.1 |

| Ammonium bicarbonate | 2.5 |

| Water | 24.5 (approximately 40°C) |

Method:

- Dissolve the ammonium bicarbonate and sulfite separately in water (ammonium is for leavening and sulfite is to reduce mix time and increase extensibility)

- Add all the ingredients into the mixer and mix at low speed for 2 minutes.

- Scrape the sides down.

- Mix it again at low speed for 14 minutes or until dough temperature reaches 40-43oC or 104-109oF (this is to make the dough pliable and extensible )

- Shape the dough into a block and use it as soon as possible to minimize the drop in dough temperature.

- Bake

Oven setting:

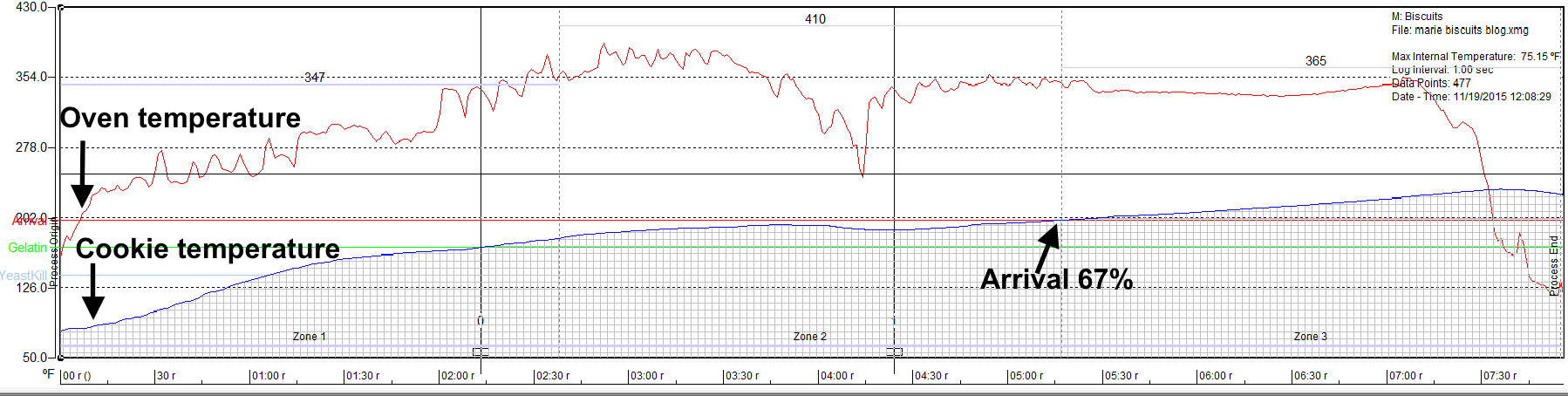

- Zone 1: 347°F (175o°C)

- Zone 2: 410°F (210°C)

- Zone 3: 365°F (185°C)

- Baking time: 6 min

The Process

Cutting dough sheets to line up for lamination.

Going through the laminator.

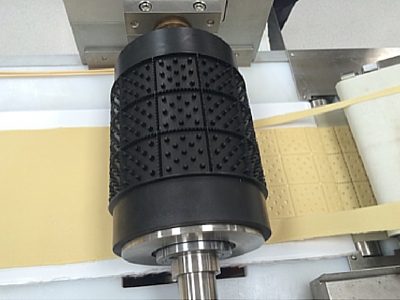

The molder.

Crackers baking on a conveyor belt in the oven.

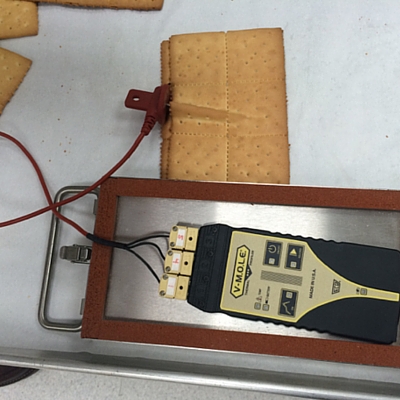

The team was curious on how the cracker baked in the oven, and so we sent our Breadometer V-mole through, sandwiched between two sheets of crackers.

We received the following thermal profile. At a maximum of 233°F (112°C) exit temperature, we reached an arrival time (200°F or 93°C) at 67% of the bake. This is a third of the bake time, spent in the crumb set zone. We believe this drives off the rest of the moisture in the cracker, leaving it to have a final moisture of less than 3%.

Thermal profile of crackers baking in the oven

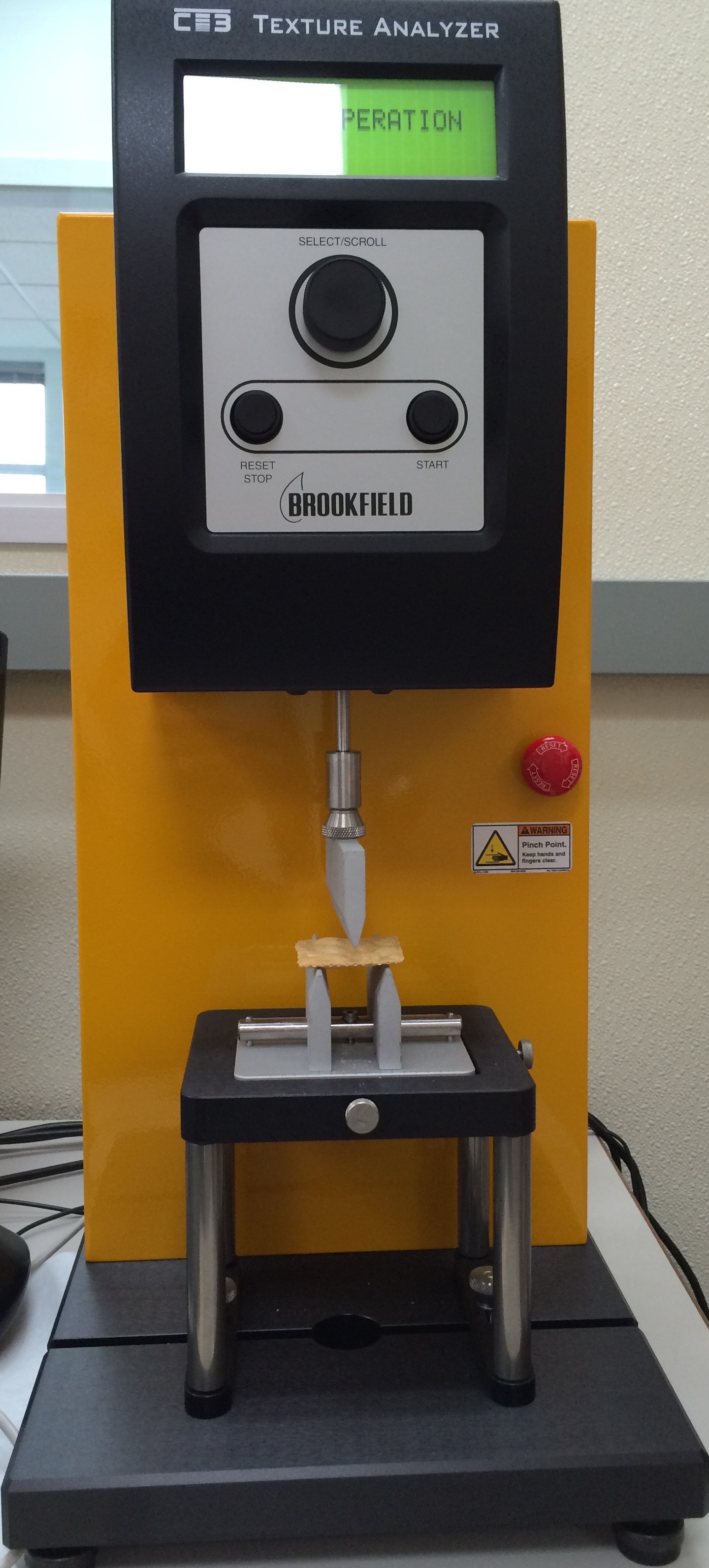

In order to understand and characterize the texture profile of the crackers, we used a texture analyzer with a three point bend test to fracture the cracker. This fracture at 3 mm was at 2000g. If quality required that this fracture be higher (or harder) >2000g, the arrival time would need to be sooner in order to drive out more moisture. This would mean the manipulation of zones 1 & 2 in the oven to bring the arrival time closer to 60%. The ability to manipulate the baking profile to affect the product’s textural attributes is critical to consistently meet texture quality parameters.

A texture analyzer

A three point bend test for a cracker:

We hope this helps you understand how you can characterize and quantify your baking process based on these tools. Any differences in ingredient or process can be seen with the a thermal profiling and quantified by a texture analyzer. Having a clear understanding of how your baking process works would yield higher quality products with less waste.